We handle any

Pressure

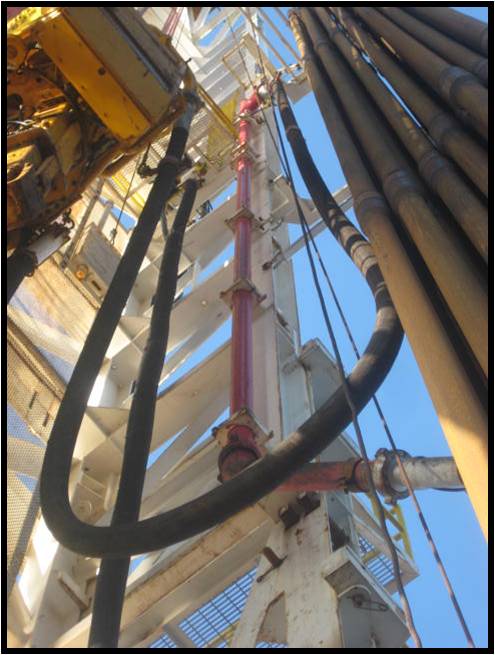

World Rig Supply: At WORLD RIG ( WRS HOSE), we understand the crucial role rotary hoses play in various industries, from drilling to mining. Our high-quality rotary hoses are designed to withstand extreme pressure and harsh conditions, ensuring durability and reliability in every application. With advanced materials and cutting-edge technology, our hoses deliver optimal performance and flexibility, reducing downtime and enhancing productivity. Discover how our rotary hoses can elevate your operations—contact us today for expert guidance and customized solutions!WRS Located in HOUSTON TEXAS is Trusted, dedicated & experinced. We are a leading supplier of High Pressure Hose & fittings, Rotary hose, Choke and kill hoses, Flexible pipe & flow line products as well as hard to find Oilfield supplies, choke lines, flow line products all at competitive prices. With same day quote and fast delivery we have been supplying a demanding worldwide oil and gas market with flexible hoses, oilfield supplies, high pressure oilfield hoses, Kelly and vibrator hoses & bop koomey hoses as well fittings connections. Whether your rig is down of you are stocking or quoting a drilling hose please let WORLD RIG SUPPLY be your chosen vendor for drilling hoses and flow line products. We think you will agree our service is unmatched in today’s industry. We take pride in offering a comprehensive selection of high-pressure hose types, including but not limited to: 1. Hydraulic Hoses: Built to endure high-pressure fluid transmission, our hydraulic hoses deliver exceptional performance and reliability. From standard to specialized hoses, we have the perfect solution for your hydraulic systems. 2. Rotary Hoses: Designed specifically for the demanding rotary drilling applications, our rotary hoses provide flexibility, durability, and excellent resistance to abrasion, corrosion, and harsh environmental conditions. 3. Choke and Kill Hoses: When it comes to well control operations, our choke and kill hoses offer reliable and safe fluid containment, ensuring efficient pressure control and preventing blowouts. 4. Cementing Hoses: Our cementing hoses are engineered to handle the high pressures and abrasive materials involved in cementing operations. They provide superior flexibility, enabling easy positioning and accurate placement of cement.

Full line OEM and aftermarket drilling spares, rig parts and machinery for the oil and gas industry. Email today for price quote for any and all drilling rig replacement spares, parts and oil tools. WORLD RIG SUPPLY, your premier destination for all your oilfield supply needs. As a leading supplier specializing in high-pressure hoses and oilfield valves, we are dedicated to providing top-quality products tailored to meet the demanding requirements of the oil and gas industry. At W.R.S, we understand the critical role that reliable equipment plays in the success of your operations. That's why we offer an extensive range of high-pressure hoses designed to withstand the harshest conditions encountered in the oilfield. Whether you require hoses for hydraulic fracturing, drilling, well servicing, or any other application, we have you covered. Our hoses are engineered to handle extreme pressures, temperature differentials, and chemical exposure, ensuring optimal performance and safety in the field. In addition to our wide range of high-pressure hoses, we also specialize in oilfield valves that are crucial components in controlling fluid flow, pressure, and safety within your operations. From gate valves and ball valves to check valves and control valves, we offer a diverse selection to suit various applications and operational requirements. WORLD RIG SUPPLY is committed to delivering exceptional customer service and building long-lasting partnerships with our clients. Our team of industry experts is ready to provide expert advice, technical support, and customized solutions to meet your specific needs. We source our products from trusted manufacturers, ensuring that you receive only the highest quality equipment that complies with industry standards and regulations. Explore our website to discover our comprehensive product catalog, technical resources, and case studies that highlight our expertise in serving the oilfield industry. Whether you are an operator, contractor, or service provider, W.R.S is your trusted partner for all your oilfield supply needs. Experience the difference with WORLD RIG SUPPLY, where quality, reliability, and exceptional service meet the demands of the oilfield. Contact us today to discuss your requirements or to speak with one of our knowledgeable team members. The oil and gas industry uses a variety of hoses for different applications, each designed to meet specific operational needs and safety standards. Here's an overview of the different types of hoses commonly found in the oil field, highlighting their uses, construction, and key features. 1. Rotary Drilling Hoses These hoses are designed to convey high-pressure drilling fluids from the top of the oil rig to the rotary swivel and drill bit. Rotary drilling hoses are built to withstand the high pressures, mechanical stress, and abrasions encountered during drilling operations. They typically feature heavy-duty reinforcement with multiple layers of steel wire and are coated with abrasion-resistant rubber or synthetic compounds. 2. Choke and Kill Hoses Choke and kill hoses are essential for controlling the flow and pressures during drilling operations. They are used in the choke and kill lines, which are critical for managing blowouts and well control issues. These hoses are designed to handle high pressures and are constructed with strong, flexible materials to ensure reliability under extreme conditions. 3. Mud Pump Hoses Mud pump hoses are used to circulate drilling mud, necessary for cooling the drill bit and carrying the cuttings back to the surface. These hoses are designed to resist the abrasive nature of the drilling mud, with durable construction that can handle high pressures. The inner linings are typically made from materials resistant to wear and corrosion. 4. Bunkering and Fuel Transfer Hoses These hoses are used for transferring fuel and other petroleum products to and from storage tanks or vehicles. Bunkering and fuel transfer hoses are designed to be flexible, durable, and resistant to oil, hydrocarbons, and other chemicals. They are constructed with layers of reinforcement for strength and are often equipped with specially designed fittings to prevent leaks and spills. 5. High-pressure Oilfield Hoses High-pressure oilfield hoses are designed for a variety of applications, including hydraulic systems, high-pressure water injection, and acidizing operations. These hoses must withstand high pressures and aggressive chemicals, making them constructed from materials that offer excellent resistance to wear, corrosion, and chemical attack. 6. Flexible Flow Lines and Manifold Hoses Flexible flow lines and manifold hoses are used to transport fluids from the wellhead to various parts of the oilfield operation. These hoses need to be highly flexible to accommodate the movement of equipment and the terrain of the oilfield. They are constructed with durable materials that can handle the pressure and flow rates of the fluids being transported. 7. Vibrator Hoses Vibrator hoses are used in conjunction with rotary drilling hoses in drilling operations to allow for vertical movement of the drill string and to absorb vibration. These hoses are constructed with reinforced rubber or synthetic materials to withstand the vibrations and stresses encountered during drilling. Conclusion The selection of hoses in the oilfield is critical to the success and safety of drilling operations. Each type of hose is designed with specific features to handle the pressures, temperatures, and materials encountered in the oil and gas industry. Quality and compliance with industry standards are paramount to ensure the integrity and reliability of these essential components. With advancements in technology, materials, and manufacturing processes, the performance and safety of oilfield hoses continue to improve, meeting the ever-increasing demands of the industry.

contact usSpecialty high pressure flexible hoses & drilling hose both low & high pressure

|

|

|