Categories

- Dm Gate Valve

- Float valve

- General Brochure

- Manifold Fittings

- Model 72 Gate Valve

- Pressure Gauges

- Pressure Relief Valve

- Reset Relief Valve

- hammer wrench

- Pipe Wipers

- Guide & Turnback

- 10 & 11 Mud Guards

- Tong and Balance

- Rig Hardware

- Rubber Products

- Statement

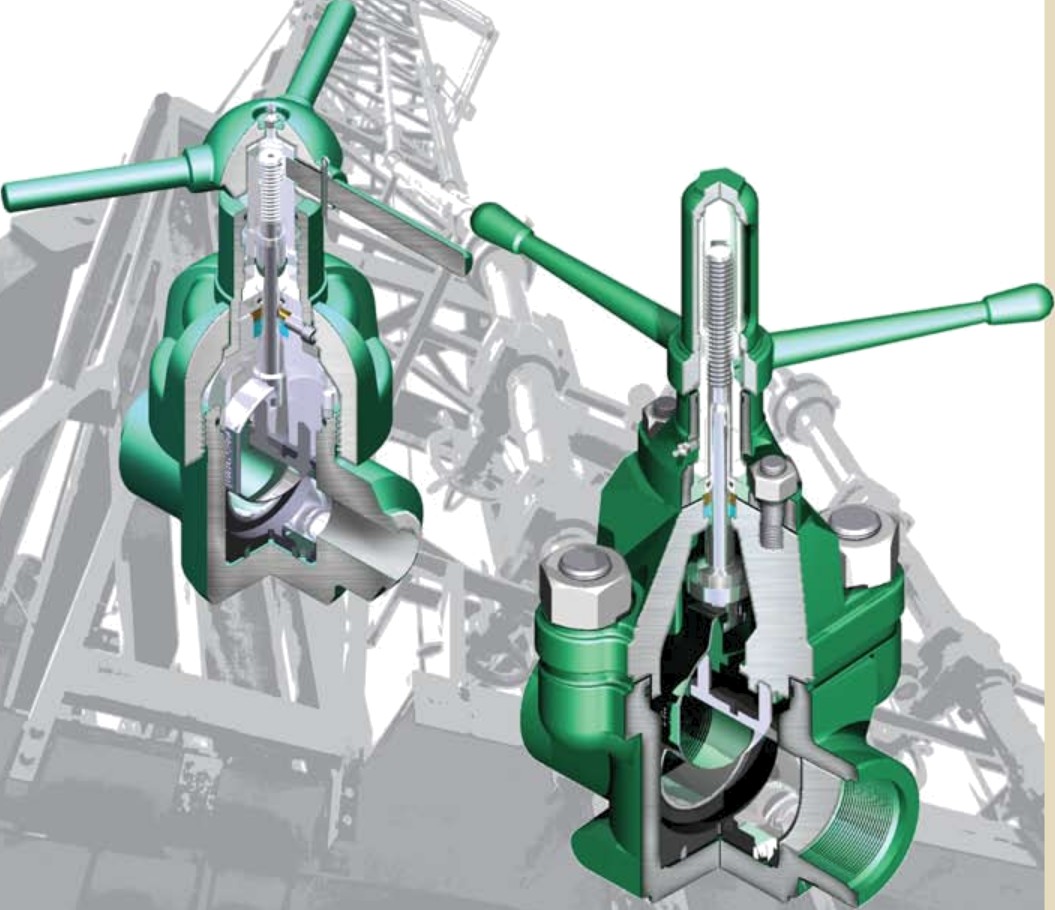

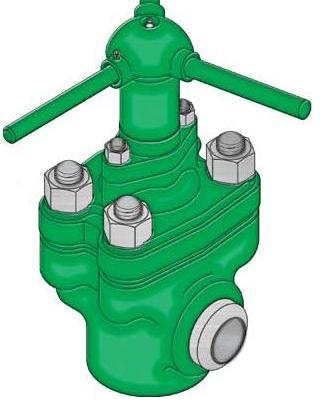

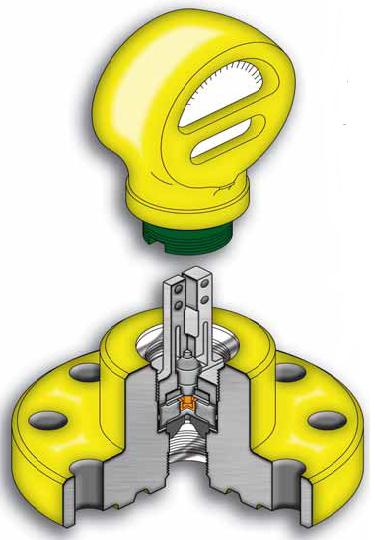

Dm Series Gate Valve Information

The OTECO DM Series Gate Valve offers low cost fluid control. For your standpipe, mud pump and other drilling and production applications where cost and easy maintenance are required. Assembled and calibrated in our Houston, Texas, USA facility.

OTECO DM Series Gate Valve

Oteco DM series fits the bill for low cost gating. Made from high strength weldable alloys and corrosion resistant components. This Water, Oil, Gas Gate Valve makes in-line repairs a cinch. Offered in pressure ranges from 0-7,500 PSI (517 BAR), Standard and Sour Gas trim options, 90 Duro main seals. Assembled and tested prior to shipment in our Houston, Texas facility.

| TRIM OPTION | MAX. WORK PRESS. | DESCRIPTION | 2”,3” INSERT | 4” INSERT | POLY | DURO | TEMP-lOW F (t) | TEMP-HIGH F IC) | BONNETSEAL-POLY | BONNETSEAL-DURO | GATE MAT’L |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SD | 5K | STANDARD | A487 | A487 | NBR | 70 | -20(-29) | 250(121) | NBR | 90 | 316SS. |

| SS | 5K | STAINLESS | 316 | 17-4 | NBR | 70 | -201-29) | 250(121) | NBR | 90 | 316SS. |

| SG | 5K | SOURGAS | 316 | 17-4 | HNBR | 80 | -40(40) | 250(121) | HNBR | 90 | 316SS. |

| HT | 5K | HIGH TEMP | 316 | 17-4 | VIT | 80 | I0(-12) | 300(149) | VIT | 90 | 316SS. |

| CS | 5K | COLD SERVICE | 316 | 17-4 | ECO | 80 | -40 (-40) | 250(121) | ECU | 90 | 316 SS. |

| HP | 7.5K | HIGH PRESSURE | A487 | 17-4 | NBR | 90 | -20 (-29) | 250(121) | NBR | 90 | 17-4 PH |

| HP/SS | 7.5K | STAINLESS | 17-4 PH | 17-4 | NBR | 90 | -20(-29) | 250(121) | NBR | 90 | 17-4 PH |

| HP/SO | 7.5K | SOUR GAS | 17-4 PH | 17-4 | HNBR | 80 | -401-40) | 250(1211 | HNBR | 90 | 17-4 PH |

| HP/lIT | 7.5K | HIGH TEMP | 17-4 PH | 17-4 | VLT | 80 | 10 (-12) | 300(149) | VIT | 90 | 17-4 PH |

| HP/CS | 7.5K | COLD SERVICE | 17-4 PH | 17-4 | HNBR | 80 | -401-40) | 250(121) | HNBR | 90 | 17-4 PH |

Features & Benefits

- - Tight fit tolerances.

- - Corrosion resistant Gate & Stem.

- - Easy in-line rebuild.

- - Integral outlet ends.

- - High strength steel seat inserts.

- - USA molded seats.

| Oteco DM Model 22, 23 & 25 Data | Models | |

|---|---|---|

| WORKING PRESS. PSI (BAR) | 2,000 (138) | 22 |

| WORKING PRESS. PSI (BAR) | 3,000 (207) | 23 |

| WORKING PRESS. PSI (BAR) | 5,000 (345) | 25 |

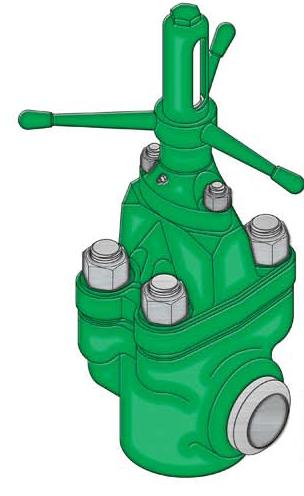

DM Series Gate Valve Information

OTECO Model 35, 28 & 38 DM Gate Valve

Feature & Benefits- Tight fit tolerances.

- Corrosion resistant Gate & Stem.

- High strength weldable alloy.

- Flourotrel lipcup stem seals.

- Zinc Chromate plated studs & nuts.

- High strength steel seat inserts.

- Extended Body Stud thread engagement.

| Oteco DM Model 35, 28 & 38 Data | Models | |

|---|---|---|

| WORKING PRESS. PSI (BAR) | 5.000 (345) | 35 |

| WORKING PRESS. PSI (BAR) | 7.500 (517) | 28, 38 |

OTECO Model 45, 55, 48 & 58 DM Gate Valve

- Tight fit tolerances.

- Corrosion resistant Gate & Stem.

- High strength weldable alloy.

- Flourotrel lipcup stem seals.

- Zinc Chromate plated studs & nuts.

- High strength steel seat inserts.

- Body & Bonnet nut clearance for closed end wrenches and sockets.

- Extended Body Stud thread engagement.

| Oteco DM Model 45, 55, 48 & 58 Data | Models | |

|---|---|---|

| WORKING PRESS. PSI (BAR) | 5.000 (345) | 45. 55 |

| WORKING PRESS. PSI (BAR) | 7.500 (517) | 48, 58 |

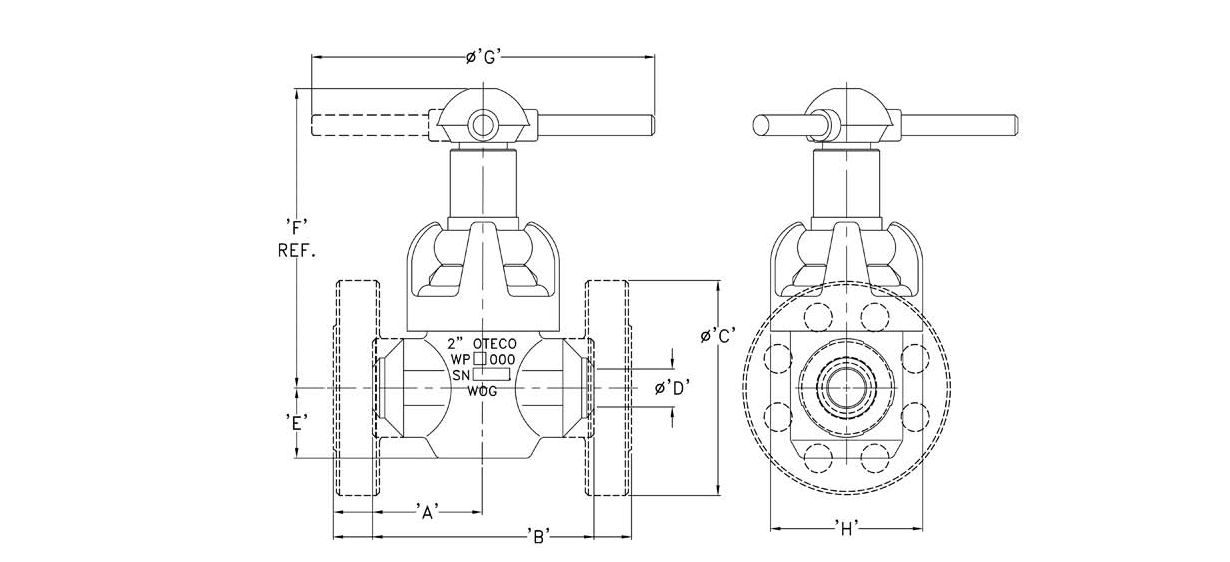

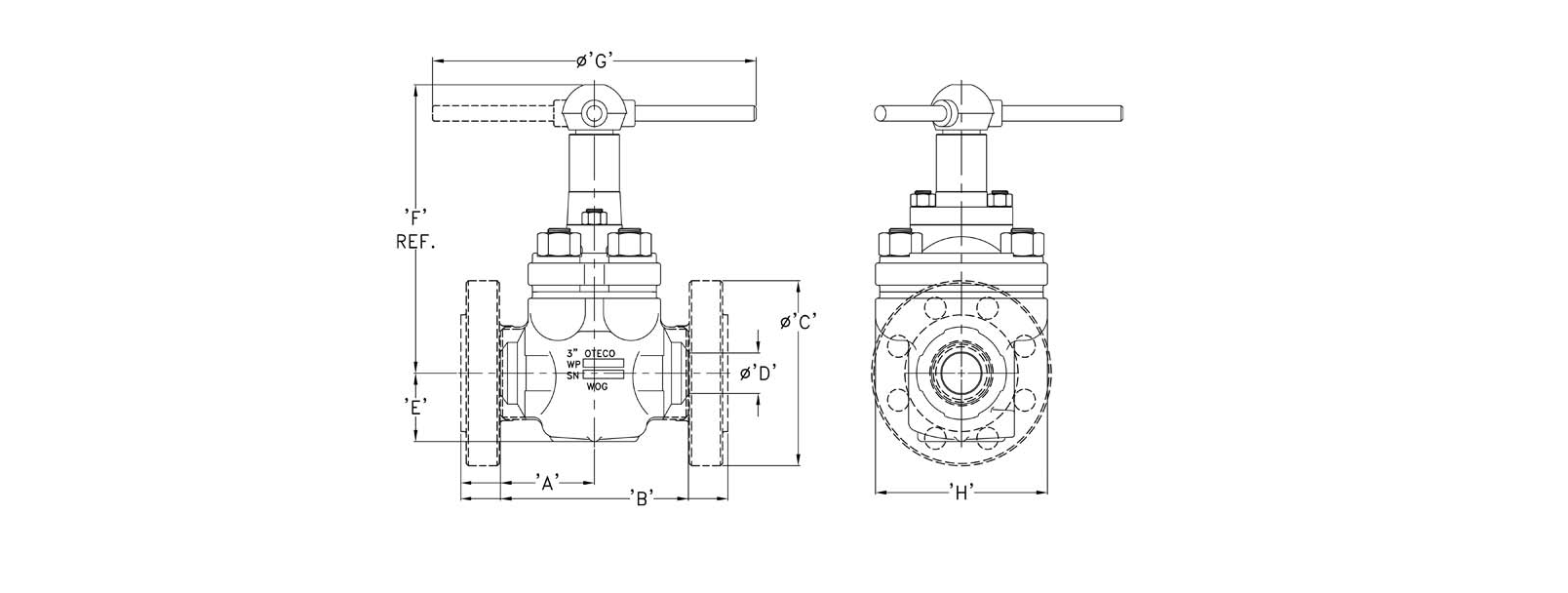

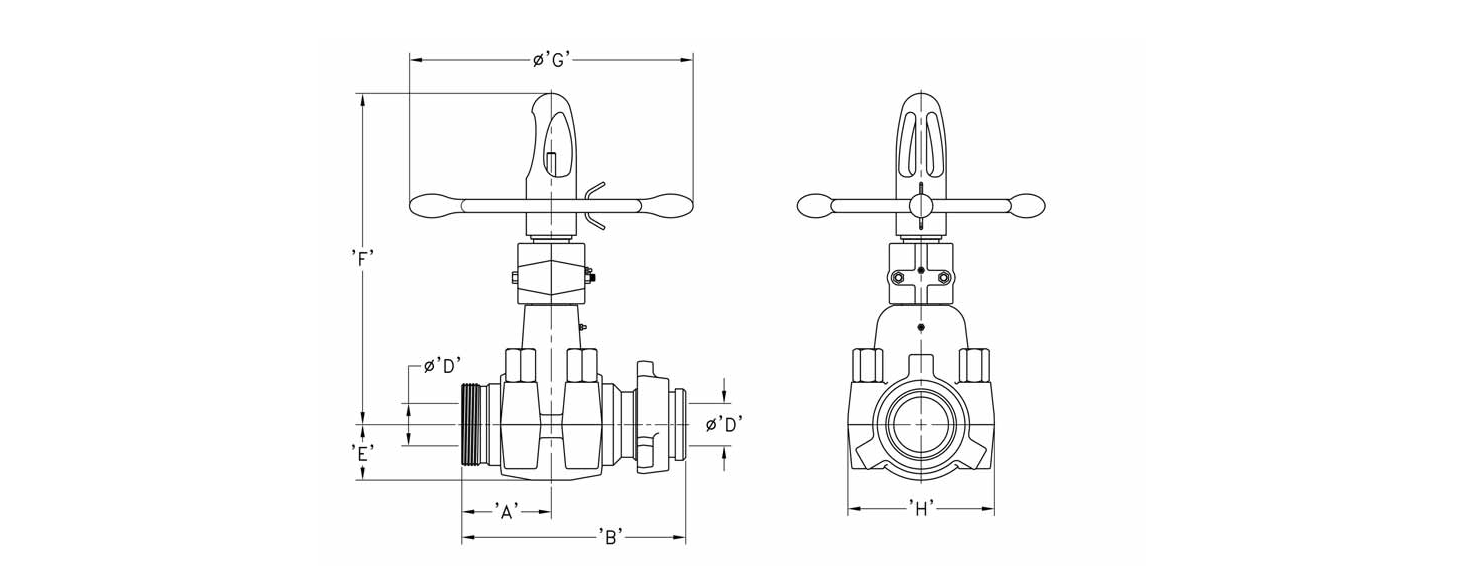

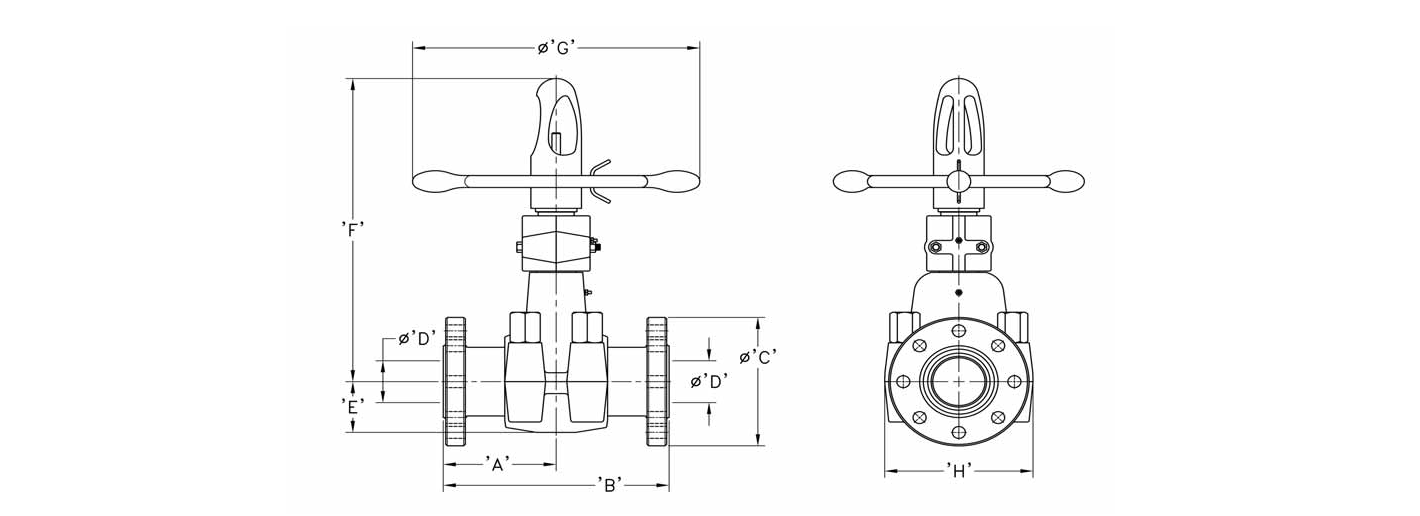

| DESCRIPTION | 'A' | 'B' | 'C' | 'D' | 'E' | 'F' | 'G' | 'H' |

|---|---|---|---|---|---|---|---|---|

| THREADED GATE VALVE, 2" LP | 4-1/2" | 9" | * | 2" | 2-3/4" | 13" | 14" | 6-3/16" |

| (114) | (229) | * | (51) | (70) | (330) | (356) | (157) | |

| BUTT WELD GATE VALVE,2" | 4-1/2" | 9" | * | *** | 2-3/4" | 13" | 14" | 6-3/16" |

| (ALL SCHEDULES ***) | (114) | (229) | * | *** | (70) | (330) | (356) | (157) |

| FLANGED GATE VALVE,2.06-5K | 6-1/16" | 12-1/8" | 8-1/2" | 2" | 2-314" | 13" | 14" | 6-3/16" |

| (RTJ-R24) | (154) | (308) | (216) | (51) | (70) | (330) | (356) | (157) |

** Dimensional values are reference Custom and non-standard end

connections will differ.

*** Butt Weld Schedules and dimensions per ANSI 636.10.

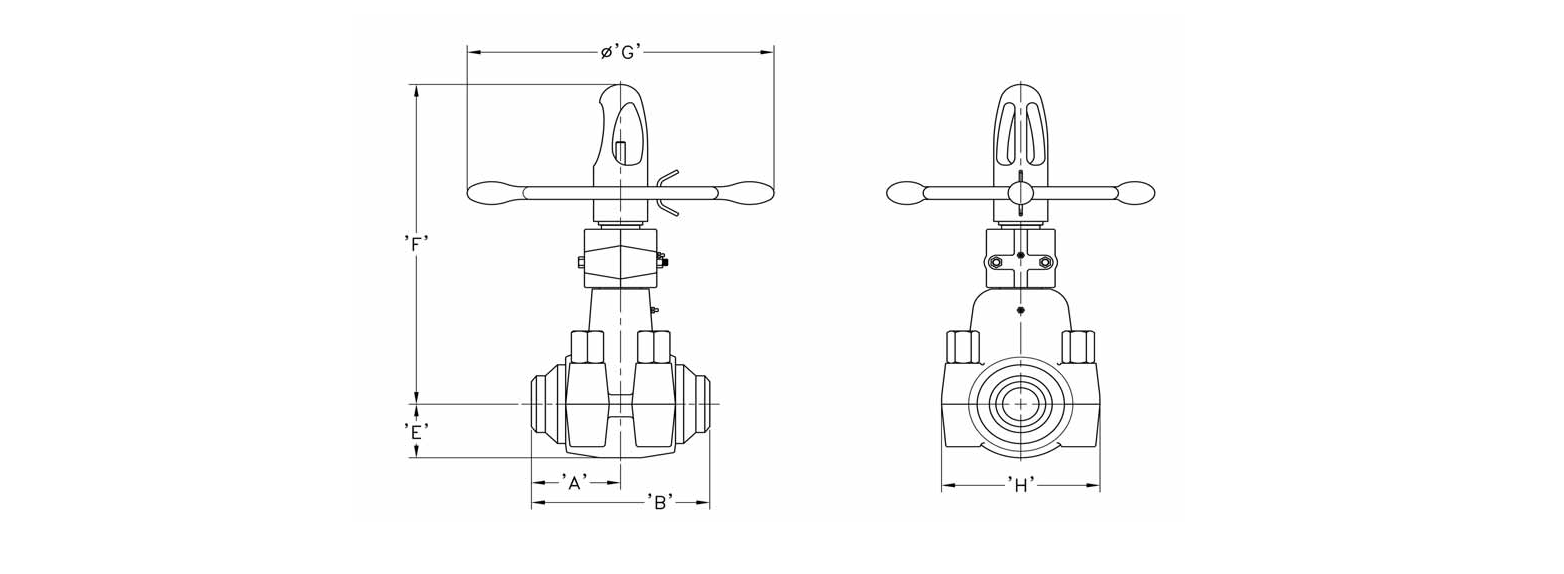

DM 35,28 & 38 SERIES GATE VALVE DIMENSIONS

| DESCRIPTION | 'A' | 'B' | 'C' | 'D' | 'E' | 'F' | 'G' | 'H' |

|---|---|---|---|---|---|---|---|---|

| DM35. THREADED GATE VALVE. 3" LP | 5-1/2" | 11" | * | 3" | 3-7/8" | 18" | 19" | 10" |

| (140) | (280) | * | (76) | (98) | (457) | (483) | (254) | |

| DM35,38.BUTT WELD GATE VALVE,3" | 5-1/2" | 11" | * | *** | 3-7/8" | 18" | 19" | 10" |

| (MODEL 38 SCH.XXS ONLY) | (140) | (280) | * | *** | (98) | (457) | (483) | (254) |

| DM28,BUTT WELD GATE VALVE,2" | 4-1/2" | 9" | * | *** | 3-7/8" | 18" | 19" | 10" |

| SCH.XXS | (114) | (229) | * | *** | (98) | (457) | (483) | (254) |

| DM35,FLANGED GATE VALVE,3.12-5K | 7-3116" | 15-5i8" | 10-1/2" | 3" | 3-7/8" | 18" | 19" | 10" |

| (RTJ-F135) | (198) | (397) | (267) | (76) | (98) | (457) | (483) | (254) |

| DM38.FLANGED GATE VALVE.3.06-10K | 12-3/16" | 24-3;8" | 10-5/8" | 3" | 3-7/8" | 18 | 19" | 10" |

| (RTJ-BX154) | (310) | (619) | (270) | (76) | (98) | (457) | (483) | (254) |

* Model 28 end to end dimensions will vary.

** Dimensional values are reference. Custom and non-standard end connections will differ.

*** Butt Weld Schedules and dimensions per ANSI B36.10.

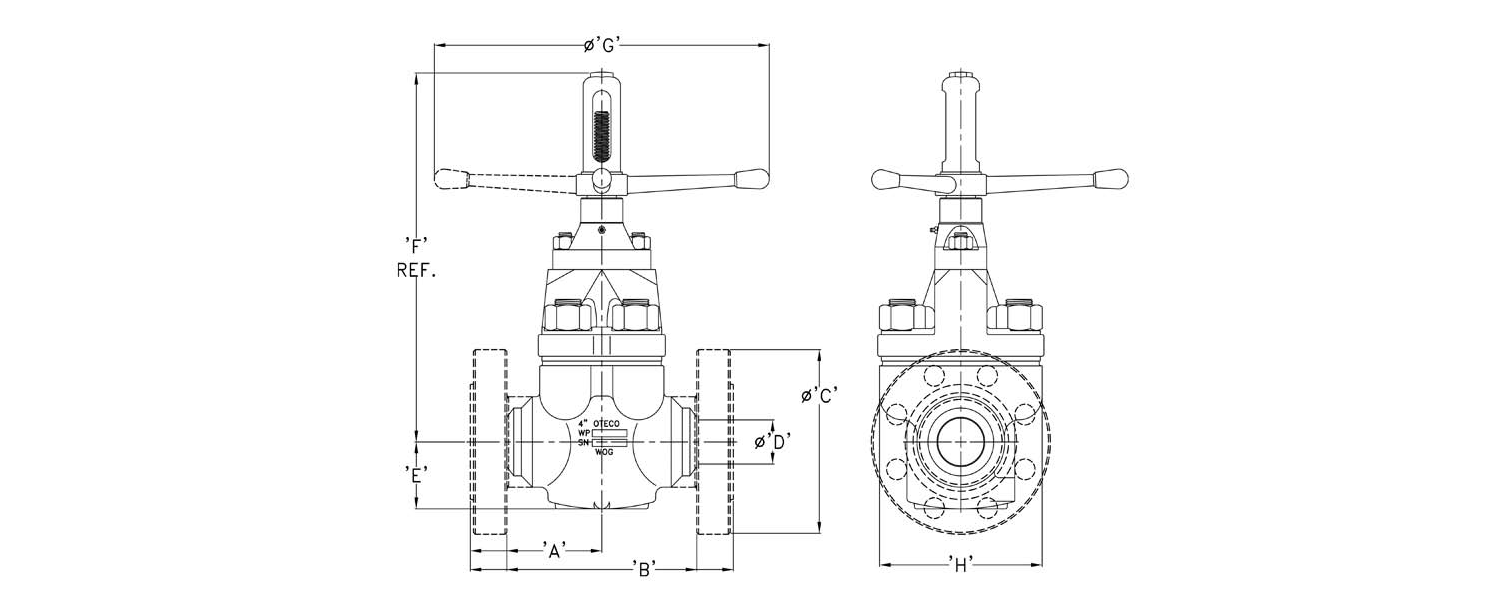

DM 45, 55, 48 & 58 SERIES GATE VALVE DIMENSIONS

| DESCRIPTION | 'A' | 'B' | 'C' | 'D' | 'E' | 'F' | 'G' | 'H' |

|---|---|---|---|---|---|---|---|---|

| DM45. THREADED GATE VALVE. 4" LP | 6-1/2" | 13" | * | 4-1/16" | 4-7/16" | 24-9/16" | 23" | 11-1/8" |

| (MODEL 45 & 48 8RD. CSG/LCSG) | (165) | (330) | * | (103) | (113) | (624) | (584) | (283) |

| DM45,48,BUTT WELD GATE VALVE.4" | 6-1/2" | 13" | * | *** | 4-7/16" | 24-9/16" | 23" | 11-1/8" |

| (MODEL 48 SCH.XXS ONLY) | (165) | (330) | * | *** | (113) | (624) | (584) | (283) |

| DM55. 58 BUTT WELD GATE VALVES" | 6-1/2" | 13" | * | *** | 4-7/16" | 24-9/16" | 23" | 11-1/8" |

| (MODEL 58 SCH.XXS ONLY) | (165) | (330) | * | *** | (113) | (624) | (584) | (283) |

| DM45.FLANGED GATE VALVE,4.06-5K | 9" | 18" | 12-1/4" | 4-1116" | 4-7/16" | 24-9/16" | 23" | 11-1/8" |

| (RTJ-R39) | (229) | (457) | (311) | (103) | (113) | (624) | (584) | (283) |

| DM48.FLANGED GATE VALVE.4.06-10K | 13-3/16" | 26-3/8" | 12-7/16" | 4-1/16" | 4-7/16" | 24-9/16" | 23" | 11-1/8" |

| (RTJ-3X155) | (335) | (670) | (316) | (103) | (113) | (624) | (584) | (283) |

| DM55.FLANGED GATE VALVE,5.12-5K | 14-1/2" | 29" | 14-3/4" | 4-1/16" | 4-7/16" | 24-916" | 23" | 1 1-1 /8" |

| (RTJ-R44) | (368) | (737) | (375) | (103) | (113) | (624) | (584) | (283) |

| DM58.FLANGED GATE VALVE5.12-10K | 14-1/2" | 29" | 14-1116" | 4-1/16" | 4-7116" | 24-9/16" | 23" | 11-1/8" |

| (RTJ-3X169) | (368) | (737) | (357) | (103) | (113) | (624) | (584) | (283) |

** Dimensional values are reference. Custom and non-standard end connections will differ.

*** Butt Weld Schedules and dimensions per ANSI B36.10.

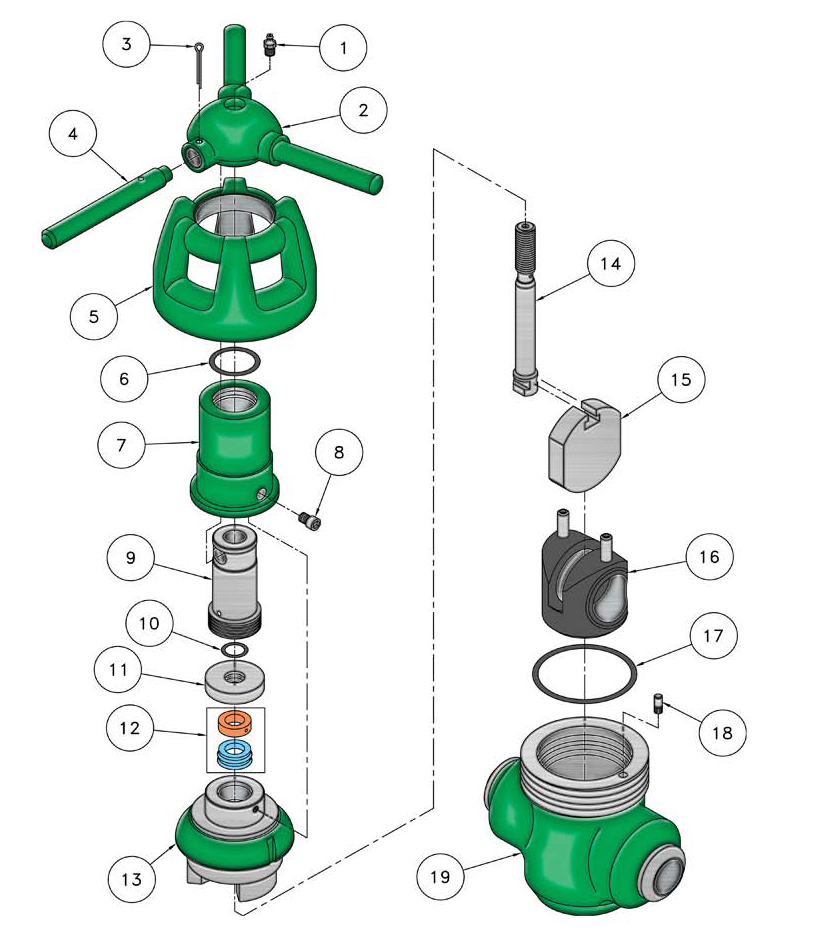

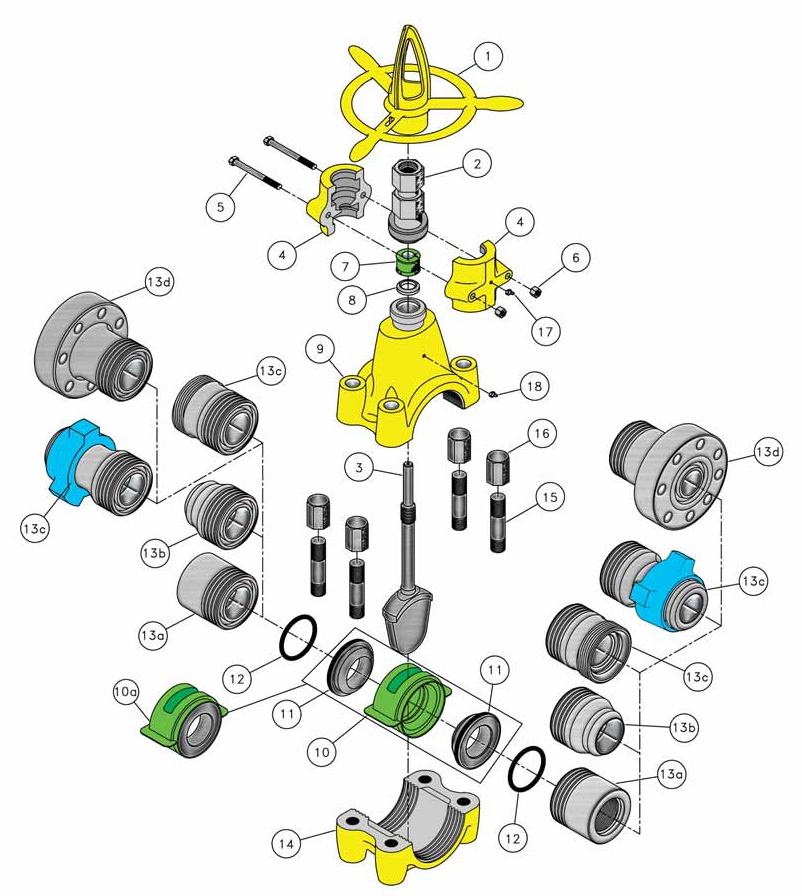

DM SERIES GATE VALVE REPAIR KITS

DM 22, 23, 25, 28, 35 & 38 SERIES GATE VALE - REPAIR KIT INFO

| Description | Assy # | SD/SS/SG/HP Mat'l |

|---|---|---|

| Gate | Item 15 | SD/SG -316 S.S. |

| HP/SG - 17-4 | ||

| Seat | Item 16 | SD - 700 NBR, Steel |

| SG - 800 HNBR, 17-4 | ||

| CS - 80D ECO, 316 S.S | ||

| SS/SG/HP - 80D HNBR, 17-4 | ||

| HP - 900 NBA, Steel | ||

| SS/HP - 90D NBA, 17-4 | ||

| Bonnet Seal | Item 17 | SD/HP - 900 NBR |

| CS - 90D HNBR | ||

| SG/HP - 90D HNBR |

| Description | Assy # | Standard Mat'l |

|---|---|---|

| Stem | Item 14 | 316 S.S. |

| Stem Seals | Item 12 | Flourotreln |

| Stem Screw | Item 9 | Steel |

| Stem Screw Seal | Item 6 | 700 NBA |

| Retainer Seal | Item 10 | 700 NBA |

* Major repair kit includes minor repair kit contents.

** Stem Seals are lipcup style with Viton Energizer

DM 45, 55, 48, 58 SERIES GATE VALE - REPAIR KIT INFO

| Description | Assy # | SD/SS/SG/HP Mat'l |

|---|---|---|

| Gate | Item 15 | SD/SG -316 S.S. |

| HP/SG - 17-4 | ||

| Seat | Item 16 | SD - 700 NBR, Steel |

| SG - 800 HNBR, 17-4 | ||

| CS - 80D ECO, 316 S.S | ||

| SS/SG/HP - 80D HNBR, 17-4 | ||

| SS/HP - 90D NBA, 17-4 | ||

| Bonnet Seal | Item 17 | SD/HP - 900 NBR |

| CS - 90D HNBR | ||

| SG/HP - 90D HNBR |

| Description | Assy # | Standard Mat'l |

|---|---|---|

| Stem | Item 14 | 316 S.S. |

| Stem Seals | Item 12 | Flourotreln |

| Stem Screw Seal | Item 6 | 700 NBR |

| Retainer | Item 11 | Steel |

| Retainer Seal | Item 10 | 700 NBA |

| Bearings | Item 18 | Teflon |

| Downstop Ring | Item 8 | Steel |

| Woodruff Key | Item 5 | Steel |

* Major repair kit includes minor repair kit contents.

** Stem Seals are lipcup style with Viton Energizer

|

|

DM SERIES GATE VALVE REPAIR KIT LIST

| OTECO PART NO. | ||||||

|---|---|---|---|---|---|---|

| DESCRIPTION | SD | SS | SG | CS | WEIGHT Lbs. (kg) | GATE VALVE DM MODEL(S) |

| MINOR REPAIR KIT,DM25 | 160121 | 3.7 (1.7) | 22, 23, 25 | |||

| MINOR REPAIR KIT,DM35 | 160131 | 8.3 (3.8) | 35 | |||

| MINOR REPAIR KIT,DM38,HP | 8.3 (3.8) | 28,38 | ||||

| MINOR REPAIR KIT,DM45 | 160141 | 15.9 (7.2) | 45, 55 | |||

| MINOR REPAIR KIT,DM48,HP | 15.9 (7.2) | 48,58 | ||||

| MAJOR REPAIR KIT,DM25 | 160122 | 6.9 (3.1) | 22, 23, 25 | |||

| MAJOR REPAIR KIT,DM35 | 160132 | 14(6.4) | 35 | |||

| MAJOR REPAIR KIT,DM38,HP | 14(6.4) | 28,38 | ||||

| MAJOR REPAIR KIT,DM45 | 160142 | 25 (11.3) | 45, 55 | |||

| MAJOR REPAIR KIT,DM48,HP | 25 (11.3) | 48,58 | ||||

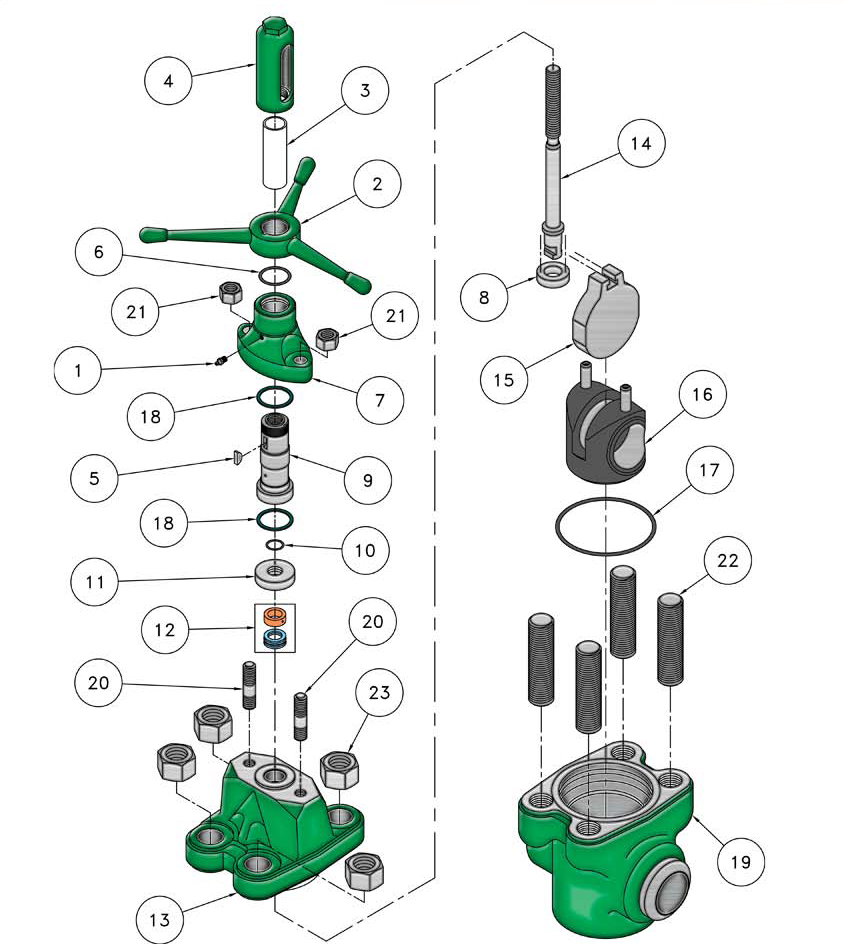

DM 22, 23 & 25 SERIES GATE VALVE PARTS

| NO. | DESCRIPTION | OTECO PART NO. | WEIGHT Lbs.(kg) | GATE VALVE DM MODEL(S) |

|---|---|---|---|---|

| ASSY | HANDLE ASSEMBLY - (ITEMS 1,2,3,4) | 160125 | 5.7 (2.6) | 22, 23, 25 |

| 1 | LUBE FITTING | 301616 | 0.1 (0.05) | 22, 23, 25 |

| 2 | HANDLE - A536 | 160102 | 4.6 (2.1) | 22, 23, 25 |

| 3 | PIN, LOCK HANDLE | 301594 | 0.1 (0.05) | 22, 23, 25 |

| 4 | LOCK HANDLE -STEEL | 160112 | 0.9 (0.4) | 22, 23, 25 |

| 5 | COUPLING - A487-4A | 161325 | 12.2 (5.5) | 22, 23, 25 |

| 6 | STEM SCREW SEAL - 70Duro NBA | 302740 | 0.1 (0.05) | 22, 23, 25 |

| 7 | SCREW HOUSING - STEEL | 161225 | 3.5 (1.6) | 22, 23, 25 |

| 8 | LOCK SCREW | 302751 | 0.1 (0.05) | 22, 23, 25 |

| 9 | STEM SCREW - STEEL | 161125 | 1.9 (0.9) | 22, 23,25 |

| 10 | RETAINER SEAL - 70Duro NBR | 302741 | 0.1 (0.05) | 22, 23, 25 |

| 11 | RETAINER - STEEL | 161302 | 0.5 (0.2) | 22, 23, 25 |

| 12 | STEM SEAL ASSEMBLY,SD/SG FLOUROTREL W/BRONZE |

160725 | 0.2 (0.1) | 22, 23, 25 |

| 13 | BONNET,SD - A487-4C | 161425 | 5.6 (2.5) | 22, 23, 25 |

| 14 | STEM,SD/SG - 316 S.S. | 160425 | 0.9 (0.4) | 22, 23, 25 |

| 15 | GATE,SD/SG - A351-CF8M (316 S.S.) | 160325 | 2(0.9) | 22, 23,25 |

| 16 |

|

161725 |

|

|

| 17 |

|

|

|

|

| 18 | INDEX PIN | 161001 | 0.1 (0.05) | 22, 23, 25 |

| 19 |

|

|

|

|

|

|

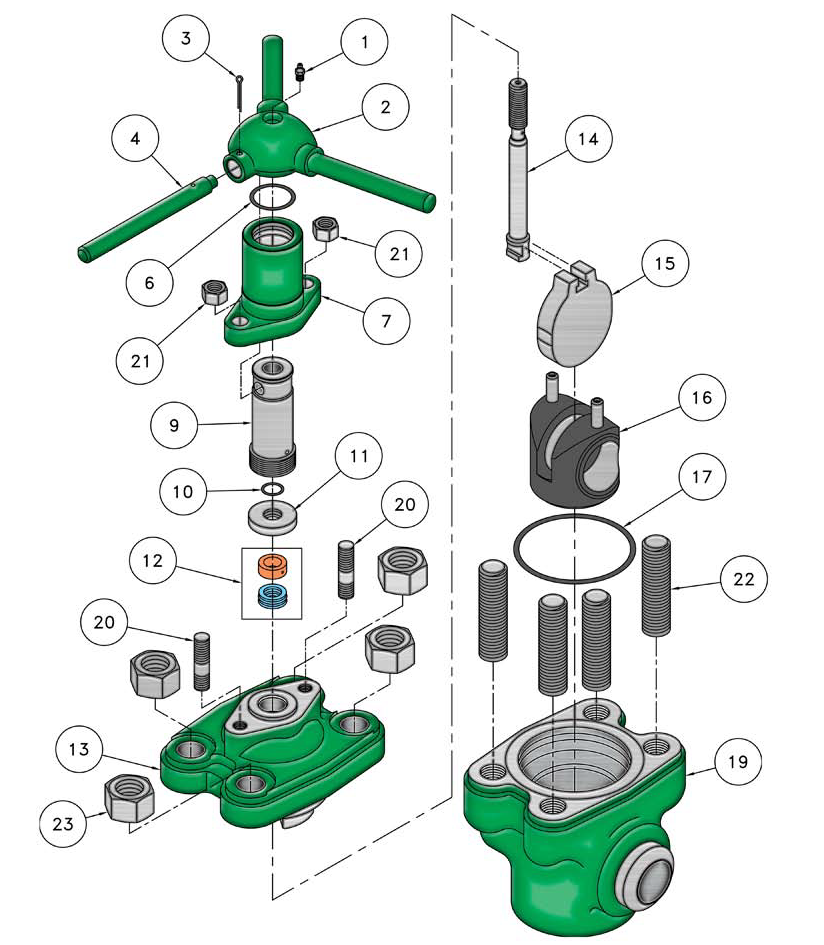

DM 35, 28 & 38 SERIES GATE VALVE PARTS

| NO. | DESCRIPTION | OTECO PART NO. | WEIGHT Lbs.(kg) | GATE VALVE DM MODEL(S) |

|---|---|---|---|---|

| ASSY | HANDLE ASSEMBLY - (ITEMS 1,2,3,4) | 160135 | 8.1 (3.7) | 35, 28, 38 |

| 1 | LUBE FITTING | 301616 | 0.1 (0.05) | 35, 28, 38 |

| 2 | HANDLE - A536 | 160103 | 6.5 (2.9) | 35, 28, 38 |

| 3 | PIN, LOCK HANDLE | 301596 | 0.1 (0.05) | 35, 28, 38 |

| 4 | LOCK HANDLE -STEEL | 160113 | 1.5 (0.7) | 35, 28, 38 |

| 6 | STEM SCREW SEAL - 70Duro NBR | 302746 | 0.1 (0.05) | 35, 28, 38 |

| 7 | SCREW HOUSING - A216 WCC | 161235 | 5.8 (2.6) | 35, 28, 38 |

| 9 | STEM SCREW - STEEL | 161135 | 3.6 (1.6) | 35, 28, 38 |

| 10 | RETAINER SEAL - 70Duro NBR | 302755 | 0.1 (0.05) | 35, 28, 38 |

| 11 | RETAINER - STEEL | 161303 | 0.5 (0.2) | 35, 28, 38 |

| 12 | STEM SEAL ASSEMBLY,SD/SG/HP FLOUROTREL W/BRONZE |

160735 | 0.2 (0.1) | 35, 28, 38 |

| 13 | BONNET,SD - A487-4D | 161435 | 39 (17.7) | 35, 28, 38 |

| 14 | STEM,SD/SS/SG/HP - 316 S.S. | 160435 | 1.7 (0.8) | 35, 28, 38 |

| 15 |

|

|

|

|

| 16 |

|

161735 |

|

|

| 17 |

|

|

|

|

| 19 |

|

|

|

|

| 20 | BONNET STUD | 160535 | 0.3 (0.14) | 35, 28, 38 |

| 21 | BONNET STUD NUT | 160635 | 0.2 (0.1) | 35, 28, 38 |

| 22 | BODY STUD | 161535 | 2 (0.9) | 35, 28, 38 |

| 23 | BODY STUD NUT | 161635 | 1(0.5) | 35, 28, 38 |

|

|

DM 45, 55, 48 & 58 SERIES GATE VALVE PARTS

| NO. | DESCRIPTION | OTECO PART NO. | WEIGHT Lbs.(kg) | GATE VALVE DM MODEL(S) | |

|---|---|---|---|---|---|

| 1 | LUBE FITTING | 301616 | 0.1 (0.05) | 45, 55, 48, 58 | |

| 2 | HANDLE - A536 | 160104 | 8.4 (3.8) | 45, 55, 48, 58 | |

| 3 | TUBE | 160110 | 0.1 (0.05) | 45, 55, 48, 58 | |

| 4 | STEM CAP - A536 | 160114 | 3(1.4) | 45, 55, 48, 58 | |

| 5 | KEY - #1008 WOODRUFF | 160115 | 0.1 (0.05) | 45, 55, 48, 58 | |

| 6 | STEM SCREW SEAL - 70Duro NBR | 302746 | 0.1 (0.05) | 45, 55, 48, 58 | |

| 7 | SCREW HOUSING - A216 WCC | 161245 | 8(3.6) | 45, 55, 48, 58 | |

| 8 | DOWNSTOP RING - STEEL | 161014 | 0.5 (0.2) | 45, 55, 48, 58 | |

| 9 | STEM SCREW - STEEL | 161145 | 3.7 (1.7) | 45, 55, 48, 58 | |

| 10 | RETAINER SEAL - 70Duro NBA | 302747 | 0.1 (0.05) | 45, 55, 48, 58 | |

| 11 | RETAINER - STEEL | 161304 | 0.9 (0.4) | 45, 55, 48, 58 | |

| 12 | STEM SEAL ASSEMBLY,SD/SG/HP FLOUROTREL W/BRONZE |

160745 | 0.2 (0.1) | 45, 55, 48, 58 | |

| 13 | BONNET,SD - A487-4D | 161445 | 68 (31) | 45, 55, 48, 58 | |

| 14 | STEM,SD/SS/SG/HP - 316 S.S. | 160445 | 3.4 (1.5) | 45, 55, 48, 58 | |

| 15 |

|

|

|

|

|

| 16 |

|

161745 |

|

|

|

| 17 |

|

|

|

|

|

| 18 | BEARING | 161000 | 0.1 (0.05) | 45, 55, 48. 58 | |

| 19 |

|

|

|

|

|

| 20 | BONNET STUD | 160545 | 0.5 (0.2) | 45, 55, 48. 58 | |

| 20 | BONNET STUD | 160545 | 0.5 (0.2) | 45, 55, 48. 58 | |

| 21 | BONNET STUD NUT | 160645 | 0.3 (0.14) | 45, 55, 48. 58 | |

| 22 | BODY STUD | 161545 | 4.3 (2.0) | 45, 55, 48. 58 | |

| 23 | BODY STUD NUT | 161645 | 2(0.9) | 45, 55, 48. 58 |

|

|

MOST COMMON DM SERIES GATE VALVE ASSEMBLIES LIST

| DESCRIPTION | OTECO PART NO. | WEIGHT Lbs.(kg) |

|---|---|---|

| GATE VALVE,DM,22,SD,2" L.P.T. | 152201 | 60 (27) |

| GATE VALVE,DM,22,SD,2" B.W. SCH.160 | 152203 | 60 (27) |

| GATE VALVE,DM,22,SD,2" B.W. SCH.XXS | 152204 | 60 (27) |

| GATE VALVE,DM,23,SD,2" L.P.T. | 152301 | 60 (27) |

| GATE VALVE,DM,23,SD,2" B.W. SCH.160 | 152303 | 60 (27) |

| GATE VALVE,DM,23,SD,2" B.W. SCH.XXS | 152304 | 60 (27) |

| GATE VALVE,DM,25,SD,2" L.P.T. | 152501 | 60 (27) |

| GATE VALVE,DM,25,SD,2" B.W. SCH.160 | 152503 | 60 (27) |

| GATE VALVE,DM,25,SD,2" B.W. SCH.XXS | 152504 | 60 (27) |

| GATE VALVE,DM,28,HP,2" B.W. SCH.XXS | 152804 | 151 (68) |

| GATE VALVE,DM,35,SD,3" L.P.T. | 153501 | 154 (70) |

| GATE VALVE,DM,35,SD,3" B.W. SCH.160 | 153503 | 154 (70) |

| GATE VALVE,DM,35,SD,3" B.W. SCH.XXS | 153504 | 154 (70) |

| GATE VALVE,DM,38,HP,3" B.W. SCH.XXS | 153804 | 154 (70) |

| GATE VALVE,DM,45,SD,4" L.P.T. | 154501 | 246 (112) |

| GATE VALVE,DM,45,SD,4" B.W. SCH.160 | 154503 | 244 (111) |

| GATE VALVE,DM,45,SD,4" B.W. SCH.XXS | 154504 | 246 (112) |

| GATE VALVE,DM,55,SD,5" B.W. SCH.XXS | 155504 | 249 (113) |

| GATE VALVE,DM,48,HP,4" B.W. SCH.XXS | 154804 | 246 (112) |

| GATE VALVE,DM,58,HP,5" B.W. SCH.XXS | 155804 | 249 (113) |

Recommended Maximum Working Pressure (WP) and Shell Test Pressure (TP) by End Connection PSI BAR

| 2.000" PORT (50.8 mm) | 3.000" PORT (76.2 mm) | 4.09" PORT (103.9 mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| END CONNECTION (WP) | DM22 2,000 (138) | DM23 3,000 (207) | DM25 5,000 (345) | DM28 7,500 (517) | DM35 5,000 (345) | DM38 7,500 (517) | DM45 5,000 (345) | DM48 7.500 (517) | DM55 5,000 (345) | DM58 7.500 (517) |

| Line Pipe Thread (TP) | 4,000 (276) | 6,000 (414) | 10,000 (689) | NA NA | 7,500 (517) | NA NA | 7,500 (517) | NA NA | NA NA | NA NA |

| 8RD. ShorVLong (TP) Casing | NA NA | NA NA | NA NA | NA NA | NA NA | NA NA | 10,000 (689) | 11,250 (776) | NA NA | NA NA |

| Butt Weld SCH.160 (TP) | 4,000 (276) | 6,000 (414) | 7,500 (517) | NA NA | 7,500 (517) | NA NA | 7,500 (517) | NA NA | 7,500 (517) | NA NA |

| Butt Weld SCH.XXS (TP) | 4,000 (276) | 6,000 (414) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) |

| RTJ Flange (TP) (API) | 4,000 (276) | 6,000 (414) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) | 10,000 (689) | 11,250 (776) |

Float valve

OTECO drill pipe Float Valves and Baffle Plates offer high quality single piece body construction for your every need. We offer our models in plunger or flapper style with automatic fill and pressure monitoring capability. Seals for both Standard and Sour Gas (H2S) service.

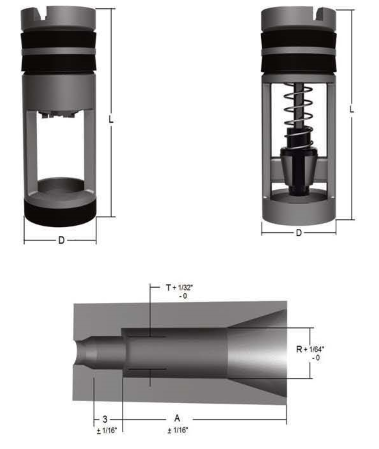

FLOAT VALVE OVERVIEW

OVERVIEW

Valve Body

Otero valve bodies are manufactured for tocIay's increasingly harsh drilling environment. All valve bodies are cast out of ductile iron or a low-alloy carbon steel and are heat treated to a hardness equal to or less than 22 Rockwell C (:S 22 Rockwell C 2 HR) to address the corrosive effects of hydrogen sulfide gas (H,S). Oteco's integral valve bodies are manufactured from a one-piece casting and are not welded together the way some other competitors produce their bodies. This means that you receive a superior and more reliable valve body.Integral Plunger Valves

All of Oteco's plunger valves are machined from one solid piece of material to produce a more reliable float valve and reduce the risk of downhole valve failure. Other leading manufacturers use two separate pieces of material to construct their plungers, which are invariably either shrunk fit, saewed or welded together.Flapper Valves

All Oteco standard-service Happer valves are made of low-alloy steel and then case hardened for wear resistance, thus giving a longer operating life.Elastomers

Available elastomers are nitrile butadiene (NBR, Buna-N), hydrogenated nitrile butadiene (HNBR) and Viton® (Huoroelastomer, FKM).Springs

Inconel® springs come standard on all our valves. Inconel® springs are significantly more resistant to corrosion when compared with the standard service springs provided by most other manufacturers. Inconel® springs are also good for sour-gas (H,S) applications.Interchangeability

All Oteco drill-pipe Hoat valves and replacement parts are manufactured to standard indusby dimensions and are interdlangeable with other major manufacturers parts.Sour-Gas (H,S) Service

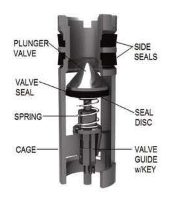

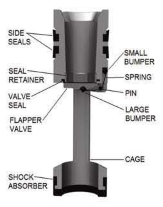

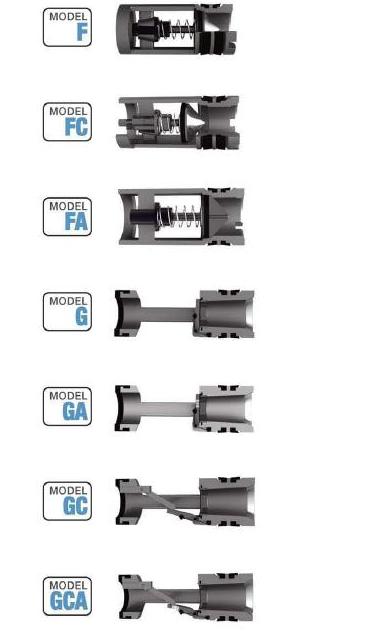

Available in both F and G models. The information contained in this catalog is not intended to be used as an operational guide. It is intended to provide a product and usage overview.PLUNGER-TYPE FLOAT VALVES

PLUNGER TYPE STANDARD

The Model F is a plunger·type float valve that provides a positive in stantaneous shut off, providing constant fluid control while drilling. The Model F is a reliable and economical selection under standard drilling operations

PLUNGER TYPE AUTOMATIC FILL

The Model Fe Automatic-Fill plunger-type float valve incorporates a unique key assembly and slotted valve stem to hold the plunger open during run in of the drill pipe and allows the pipe to fill from the bot- tom, saving time, reducing mess, and avoiding hazards. The plunger is automatically released once circulation begins

PLUNGER TYPE PRESSURE MONITORING

The Model FA Pressure-Monitoring plunger-type float valve has a special port running through the plunger of the float valve. This valve is used when monitoring the bit head for gas pressure and allowing dif- ferential pressure measuring when required. The port also permits partial automatic fill during run in.

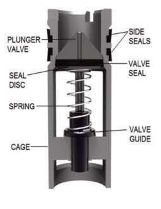

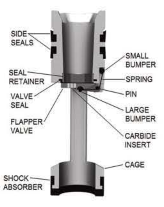

FLAPPER TYPE

STANDARD

The Mode! G is a flapper-type float valve that, when opened, offers an unobstructed bore through the float valve. The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints.

FLAPPER TYPE

PRESSURE MONITORING

The Model GA Pressure-Monitoring flapper-type float valve is indistin guishable from the Model G with the exception of a tungsten-carbide insert in the flapper valve. The insert has a quarter-inch orifice through the center that allows for differential pressure monitoring. The orifice also allows for partial automatic filling of the drill pipe during run in .

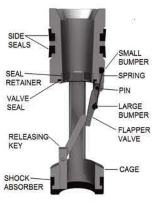

FLAPPER TYPE

AUTOMATIC FILL

The Model GC Automatic-Fill flapper-type float valve incorporates a unique self-releasing key assembly that holds the flapper partially open during run in. allowing the pipe to fill from the bottom. This elim- inates the need for filling the drill pipe from the top, saving time and money. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints while avoiding the environmental and safety risks related to having mud on the rig floor. The valve can be run with the automatic-fill option or in the standard, closed posi- tion.

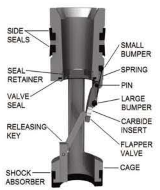

FLAPPER TYPE

AUTO FILUPRESSURE MONITORING

The Model GCA Automatic-FiIl/Pressure-Monitoring flappeHype float valve includes all the advantages of the Models G, Ge, and GA An unobstructed bore through the float valve. when open, permits auto- matic partial filling of the drillpipe from the bottom and measuring dif- ferential pressures when necessary.

A = L (Length of Float Valve) + Length of Tool Joint Pin + 1/4" Clearance

DIMENSIONAL

DATA

| ValveSize | Diameter of Valve | Diameter Recess F/Velve | WM Length | Baffle Plate Recess Diameter | Valve ID Model F | Valve ID Model F |

|---|---|---|---|---|---|---|

| 1R | I-21/32" | 1-11/16' | 5-7/8" | 1-5/6" | 1-1/4" | NA |

| 1F-2R | 1-29/32" | 1-15/16' | 6-1/4" | 1-1/2" | 1-1/4" | 1" |

| 2F-3R | 2-13/32' | 2-7/16" | 6-1/2" | 1-29/32" | 1-9/16" | 1-1/4" |

| 3F | 2-13/16" | 2-27/32' | 10" | 2-7/16" | 1-7/8" | 1-5/8" |

| 3.5IF | 3-1/8" | 3-5/32" | 10" | 2-11/16" | 1-7/8" | 1-5/8" |

| 4R | 3-15/32" | 3-1/2" | 8-5/16" | 2-15/16 | 2-5/16" | 1-31/32" |

| 4F | 3-21/32" | 3-11/16' | 12" | 3-1/4" | 2-1/2" | 2-3/16" |

| 5R | 3-7/8" | 3-29/32' | 9-3/4" | 3-3/8" | 2-3/4" | 2-1/4" |

| 5F-6R | 4-25/32" | 4-13/16' | 11-3/4" | 4-9/32" | 3-1/4" | 2-7/8" |

| 6F | 5-11/16" | 5-23/32' | 14-5/8" | 5-3/16" | 4-1/8" | NA |

"Disregard if this diameter is [he same or smaller than the standard tool joinlID.

SPECIFICATION GUIDE

TOOL JOINT

SPECIFICATION GUIDE

| Tool Joint Types | Model Sizes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| IR | 1F-2R | 2F-3R | 3F | 3.5F | 4R | 4F | 5R | 5F-6R | 6F | |

| API Regular | 2-3/8" | 2-718" | 3-1/2" | 4-1/2" | sdas | 5-1/2" 5-9/16" | 6-5/8" 7-5/8•1 | 8-5/8' | ||

| Hughes a Reed Acme | 2-3/8" | 2-7/8" | 3-1/21" | 4-1/2" | 5-1/2" 5-9/16" | 6-5/8" | ||||

| Union Tool | 2.3/8" | 2-7/8" 3-1/2" | 4-1/2" | 5-1/2" 5-9/16" | 5-6/8" | |||||

| Hughes or Reed Double Streamline | 2-7/8" 2-3/8" | 3-1/2" | 4" 4-1/2" | 5" | 5-1/2" | 5-9/16" | ||||

| API Full Hoe | 2-3/8" | 2-7/8" | 3-1/2" | 4" | 4-1/2" | 4-1/2" | 6-3/8" | |||

| Reed Acme Full Hoe | 3-1/2" | 4-1/2" | 5-1/2" 5-9/16" | |||||||

| Hughes Acme Streamline | 2-3/8" | 2-7/8" | 3-1/2" | 4-1/2" | 5-1/2"1 5-9/16" | |||||

| Hughes Xtra Kee | 2-7/8" | 2-3/8" | 4-1/2" | 5" | 5-1/2" 1 5-9/16" | |||||

| Reed Semi-Internal Flush | 2-7/8" | 2-3/8" | 4-1/2" | 5" | ||||||

| API Internal Flush | 2-3/8" | 2-7/8" | 3-1/2" | 4" | 4-1/2" | |||||

| Hydril Type IF (mnt. Flush Ext. Upset) | 2-3/8" | 2-7/8" | 3-1/2" | 4-1/2" | 5" | |||||

| Hydril EIU (Ext. Int. Upset) | 2 7/8" 3-1/2" | 3-1/2" | 4" | 4-1/2" | 5-1/2" 5-9/16" | 6-5/8" | ||||

| Hughes Ext. Rush Acme | 3-1/2" | 4-1f2" | 5-1/2" 5-9/16" | 6-5/8" | ||||||

| Hughes Ext. Rush Ful Hole | 4-1/2" |

'Indicates that the float subs in these sizes have a smaller ID than the standard tool joint 10. 'Indicates interchangeability. MOdels G and GA, are available in sizes ' F-2R through SF·6R. Models GC and GCA are avaitable in sizes 2F·3R through SF-6R. Models F and FA are available in all sizes. Model Fe is available in sizes 2F·3R through 6F,

BIT & SHANK

SIZES

| Bit Size(in.) | 3 1/2 | 3 3/8 | 4 1/2 | 4 3/4 | 5 1/2 | 6 | 6 1/8 | 6 1/4 | 6 1/2 | 6 3/4 | 7 7/8 | 8 1/4 | 8 1/2 | 8 3/4 | 9 1/2 | 9 3/4 | 10 1/2 | 11 | 12 1/4 | 13 1/2 | 20 | 24 | 25 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Std. API P" Shank Si2e (h) | 2 3/8 | 2 3/8 | 2 3/8 | 2 1/8 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 4 1/2 | 4 1/2 | 4 1/2 | 4 1/2 | 6 5/8 | 6 5/8 | 6 5/8 | 6 5/8 | 6 5/8 | 6 5/8 | 7 5/8 | 7 5/8 | 7 5/8 |

BIT SUB INFORMATION

BIT SUB

INFORMATION

| View Size | Thread Size | Tool Joint Type | Standard OD | Face To Shoulder or Face To Face |

|---|---|---|---|---|

| 1R | 2-3/8" |

API Regular |

3-1/8" | 18" |

| 1F-2R | 2-7/8" | 3-3/4" | 20" | |

| 2F-3R | 3-1/2" | 4-1/4" | 20" | |

| 4R | 4-1/2" | 5-1/2" | 24" | |

| 5R | 5-1/2" | 6-3/4" | 28" | |

| 5F-6R | 6-5/B" | 7-3/4" | 30" | |

| 5F-6R | 7-5/8" | 8-7/8" | 30" | |

| 6F | 8-5/8" | 10" | 30" | |

| 3F | 3-1/2" | API Full Hole |

4-5/8" | 24" |

| 3.5IF | 4" | 5-1/4" | 24" | |

| 4F | 4-1/2" | 5-3/4" | 28" | |

| 5F-6R | 5-1/2" | 7" | 30" | |

| 6F | 6-5/8" | 8" | 30" | |

| 1F-2R | 2-3/8" | AAIF | 3-3/8" | 18" |

| 2F-3R | 2-7/8" | APt IF Box Pin | 4-1/8" | 20" |

| 3.5IF | 3-1/2" | API IF |

4-3/4" | 24" |

| 4F | 4" | 5-3/4" | 28" | |

| 5R | 4-1/2" | 6-3/8" | 28" | |

| 5F-6R | 5-1/2" | 7-3/8" | 30" | |

| 6F | 6-5/8" | 8-3/4" | 30" |

The information guide above is for reference purposes onty. Please use appropriate API specifications when manufacturing these subs.

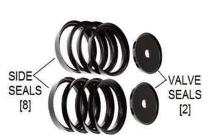

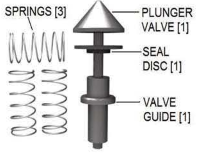

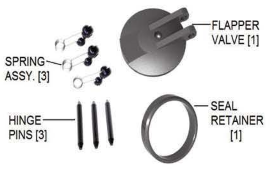

REPAIR KITS

RUBBER REPAIR KIT F

METAL REPAIR KIT F

RUBBER REPAIR KIT G

METAL REPAIR KIT G

VALVE PULLERS

MODEL F VALVE PULLER

The Model F Valve Puller makes easy work of removing stuck or tight float valves from the sub or drill collar. Simply engage the special catch into the bottom of the float valve, rotate 90°, and then simply slide the bumper into the stop and the float valve is removed.

Note: when using the puller to remove a Model Fe valve, special care must be taken when en- gaging the catch so that it does not make contact with the releaSing key.

MODEL G VALVE PULLER

The Model G Valve Puller is dual-purpose tool. In addition to removing tight or stuck float valves from subs or drill coliars, it assists in removing and installing the seal-retaining ring when chang- ing out the valve seal.

ORDERING INFORMATION

PLUNGER TYPE

Standard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1R | 480131200 | 1.5 | 15929800 | 1.0 | 16012200 | 0.5 | 911200 | 6.0 |

| 1F-2R | 480131422 | 1.5 | 16011300 | 2.0 | 16012300 | 0.7 | 9112001 | 6.0 |

| 2F-3R | 480132432 | 2.5 | 16011400 | 2.0 | 16012400 | 0.8 | 912432 | 8.0 |

| 31 | 480133400 | 5.0 | 16011500 | 2.0 | 6012500 | 1.0 | 913400 | 10.0 |

| 3.511 | 480133600 | 5.0 | 16011500 | 2.0 | 6012600 | 1.0 | 913400 | 10.0 |

| 4R | 480134200 | 7.0 | 16011700 | 2.0 | 6012700 | 1.0 | 914200 | 12.0 |

| 41 | 480134400 | 9.5 | 16011800 | 3.0 | 6012800 | 1.0 | 914400 | 13.0 |

| 5R | 480135200 | 9.5 | 16011900 | 4.0 | 6012900 | 1.0 | 914414 | 15.0 |

| 5F-6R | 480135462 | 16.0 | 16012000 | 5.0 | 6013000 | 1.1 | 914400 | 19.0 |

| 6F | 480136400 | 28.0 | 16012100 | 5.0 | 16013100 | 2.0 | 916400 | 21.0 |

PLUNGER TYPE AUTOMATIC FILL

Standard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 2F-3R | 480182432 | 2.5 | 70017100 | 2.0 | 16012400 | 0.8 | 912432 | 8.0 |

| 3F | 480183400 | 5.0 | 70017300 | 2.0 | 16012500 | 1.0 | 913400 | 10.0 |

| 3.5IF | 480183500 | 5.0 | 70017300 | 2.0 | 16012600 | 1.0 | 913400 | 10.0 |

| 4R | 480184200 | 7.0 | 70017400 | 2.0 | 16012700 | 1.0 | 914200 | 12.0 |

| 4F | 480184400 | 9.5 | 70017500 | 3.0 | 16012800 | 1.0 | 914400 | 13.0 |

| 5R | 480185200 | 9.5 | 700176C0 | 4.0 | 16012900 | 1.0 | 914400 | 15.0 |

| 5F-6R | 480183462 | 16.0 | 73017700 | 5.0 | 16013000 | 1.1 | 914400 | 19.0 |

| 6F | 480180400 | 28.0 | 70017800 | 5.0 | 16013100 | 2.0 | 916400 | 21.0 |

PLUNGER TYPE PRESSURE MONITORING

Standard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1R | 480131200 | 1.5 | 15929805 | 1.0 | 15012200 | 0.5 | 911200 | 7.0 |

| 1F-2R | 480131422 | 1.5 | 16011305 | 1.0 | 16012300 | 0.1 | 911200 | 7.0 |

| 2F-3R | 480132432 | 2.5 | 16011405 | 2.0 | 16012400 | 0.8 | 912432 | 8.0 |

| 3F | 480133400 | 5.0 | 16011505 | 2.0 | 16012500 | 1.0 | 913400 | 10.0 |

| 3.5lF | 480133600 | 5.0 | 16011505 | 2.0 | 6012600 | 1.0 | 913400 | 10.0 |

| 4R | 480134200 | 7.0 | 16011705 | 2.0 | 6012700 | 1.0 | 914200 | 12.0 |

| 4F | 480134400 | 9.5 | 16011805 | 2.0 | 6012800 | 1.0 | 914400 | 13.0 |

| 5R | 480135200 | 10.5 | 16011905 | 3.5 | 16012900 | 1.0 | 914400 | 15.0 |

| 5F-6R | 480135462 | 16.0 | 16012005 | 5.0 | 16013000 | 1.1 | 914400 | 19.0 |

| 6F | 480136400 | 28.0 | 16012105 | 5.0 | 16013100 | 12 | 916400 | 21.0 |

PLUNGER TYPE

H2S Service

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1R | 480301200 | 1.5 | 15929800 | 1.0 | 71081701 | 0.5 | 911200 | 6.0 |

| 1F-2R | 480331422 | 1.5 | 16011300 | 2.0 | 71081801 | 0.7 | 911200 | 7.0 |

| 2F-3R | 480302432 | 2.5 | 16011400 | 2.0 | 71081901 | 0.8 | 912432 | 8.0 |

| 3F | 480333400 | 5.0 | 160115C0 | 2.0 | 71082001 | 1.0 | 913400 | 10.0 |

| 3.51F | 480303600 | 5.0 | 71082101 | 2.0 | 71082101 | 1.0 | 913400 | 10.0 |

| 4R | 480304200 | 7.0 | 16011700 | 2.0 | 71082201 | 1.0 | 914200 | 12.0 |

| 4F | 480304400 | 9.5 | 16011800 | 3.0 | 71082301 | 1.0 | 914400 | 13.0 |

| 5R | 480305200 | 9.5 | 16011900 | 4.0 | 71082401 | 1.0 | 914400 | 15.0 |

| 5F-6R | 480305462 | 16.0 | 16012000 | 5.0 | 71082501 | 1.1 | 914400 | 19.0 |

| 6F | 480306400 | 28.0 | 16012100 | 5.0 | 71082601 | 2.0 | 916400 | 21.0 |

ORDERING INFORMATION

PLUNGER TYPE

Pressure MonitoringH2S Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 2F-3R | 480352432 | 2.5 | 16011405 | 2.0 | 71081901 | 0.8 | 912432 | 8.0 |

| 3F | 480353400 | 5.0 | 16011505 | 2.0 | 71082001 | 1.0 | 913400 | 10.0 |

| 3.5lF | 480353600 | 2.5 | 16011505 | 2.0 | 71082101 | 1.0 | 913400 | 10.0 |

| 4R | 480354200 | 7.0 | 16011705 | 2.0 | 71082201 | 1.0 | 914200 | 12.0 |

| 5F-6R | 480355462 | 16.0 | 16012005 | 5.0 | 71082501 | 1.1 | 914400 | 19.0 |

Flapper TYPE

Standard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1F-2R | 480151422 | 2.0 | 51988400 | 0.7 | 51988300 | 0.5 | 901422 | 7.0 |

| 2F-3R | 480152432 | 3.5 | 16013200 | 0.8 | 16013800 | 0.6 | 902432 | 8.0 |

| 3F | 480153400 | 5.0 | 16013300 | 1.0 | 16013900 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480153600 | 5.5 | 16013300 | 1.0 | 51982000 | 1.0 | 903400 | 10.0 |

| 4R | 480154200 | 7.0 | 16013400 | 1.1 | 1601400 | 0.5 | 904200 | 12.0 |

| 4F | 480154400 | 8.0 | 16013500 | 1.4 | 16014100 | 1.6 | 904400 | 13.0 |

| 5R | 480155200 | 9.0 | 16013600 | 1.6 | 16014200 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480155462 | 18.0 | 16013700 | 1.8 | 16014300 | 2.0 | 905463 | 19.0 |

Flapper TYPE

Pressure MonitoringStandard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1F-2R | 480161422 | 2.0 | 52070800 | 0.7 | 51988300 | 0.5 | 901422 | 7.0 |

| 2F-3R | 480162432 | 3.5 | 17135000 | 0.8 | 16013800 | 0.6 | 902432 | 8.0 |

| 3F | 480163400 | 5.0 | 17136700 | 1.0 | 16013900 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480163600 | 5.5 | 17136700 | 1.0 | 51982000 | 1.0 | 903400 | 10.0 |

| 4R | 480164200 | 7.0 | 17116000 | 1.1 | 1601400 | 0.5 | 904200 | 12.0 |

| 4F | 480164400 | 8.0 | 17136800 | 1.4 | 16014100 | 1.6 | 904400 | 13.0 |

| 5R | 480165200 | 9.0 | 17136900 | 1.6 | 16014200 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480165462 | 18.0 | 17134200 | 1.8 | 16014300 | 2.0 | 905463 | 19.0 |

FLAPPER TYPE

AUTOMATIC FILLStandard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 2F-3R | 480192432 | 3.5 | 16013200 | 0.8 | 16013800 | 0.6 | 902432 | 8.0 |

| 3F | 480193400 | 5.0 | 16013300 | 1.0 | 16013900 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480193600 | 5.5 | 16013300 | 1.0 | 51982000 | 1.0 | 903400 | 10.0 |

| 4R | 480194200 | 7.0 | 16013400 | 1.1 | 1601400 | 0.5 | 904200 | 12.0 |

| 4F | 480194400 | 8.0 | 16013500 | 1.4 | 16014100 | 1.6 | 904400 | 13.0 |

| 5R | 480195200 | 9.0 | 16013600 | 1.6 | 16014200 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480195462 | 18.0 | 16013700 | 1.8 | 16014300 | 2.0 | 905463 | 19.0 |

FLAPPER TYPE

AUTO FILL/ Pressure MonitoringStandard Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 2F-3R | 480192432 | 3.5 | 17135000 | 0.8 | 16013800 | 0.6 | 902432 | 8.0 |

| 3F | 480193401 | 5.0 | 17136700 | 1.0 | 16013900 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480193601 | 5.0 | 17136700 | 1.0 | 51982000 | 1.0 | 903400 | 10.0 |

| 4R | 480194201 | 7.0 | 17116000 | 1.1 | 16014000 | 1.5 | 904200 | 12.0 |

| 4F | 480194401 | 8.0 | 17136800 | 1.4 | 16014100 | 1.6 | 904400 | 13.0 |

| 5R | 480195201 | 9.0 | 17136900 | 1.6 | 16014200 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480195463 | 18.0 | 16013700 | 1.8 | 17134200 | 2.0 | 905462 | 19.0 |

FLAPPER TYPE

H2S Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1F-2R | 480311422 | 2.0 | 51997300 | 0.7 | 51997200 | 0.5 | 901422 | 7.0 |

| 2F-3R | 480312432 | 3.5 | 71085901 | 0.8 | 71082701 | 0.6 | 902432 | 8.0 |

| 3F | 480313400 | 5.0 | 71086001 | 1.0 | 71082801 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480313600 | 5.0 | 71086001 | 1.0 | 52125001 | 1.0 | 903400 | 10.0 |

| 4R | 480314200 | 7.0 | 71086101 | 1.1 | 71082901 | 1.5 | 904200 | 12.0 |

| 4F | 480314400 | 8.0 | 71086201 | 1.4 | 71083001 | 1.6 | 904400 | 13.0 |

| 5R | 480315200 | 9.0 | 71086301 | 1.6 | 71083101 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480315462 | 18.0 | 71086401 | 1.8 | 71083201 | 2.0 | 905462 | 19.0 |

FLAPPER TYPE

Pressure MonitoringH2S Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1F-2R | 480261422 | 2.0 | 5207080 | 0.7 | 51997200 | 0.5 | 901422 | 7.0 |

| 2F-3R | 480262432 | 3.5 | 17135001 | 0.8 | 71082701 | 0.6 | 902432 | 8.0 |

| 3F | 480263400 | 5.0 | 17136701 | 1.0 | 71082801 | 1.0 | 903400 | 10.0 |

| 3.5lF | 480263600 | 5.0 | 17036701 | 1.0 | 52125001 | 1.0 | 903400 | 10.0 |

| 4R | 480264200 | 7.0 | 17116001 | 1.1 | 71082901 | 1.5 | 904200 | 12.0 |

| 4F | 480264400 | 8.0 | 17136801 | 1.4 | 71083001 | 1.6 | 904400 | 13.0 |

| 5R | 480265200 | 9.0 | 17136901 | 1.6 | 71083101 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480265462 | 12.0 | 17134201 | 1.8 | 71083201 | 2.0 | 905462 | 19.0 |

FLAPPER TYPE

Automatic FillH2S Service.

| Size | Assembly | Weight (lbs.) | Metal Repair Kit | Weight (lbs.) | Rubber Repair Kit | Weight lbs.) | Puller Assembly | Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|

| 2F-3R | 480332432 | 3.5 | 71085901 | 0.8 | 16013800 | 0.6 | 902432 | 8.0 |

| 3F | 480333400 | 5.0 | 71086001 | 1.0 | 16013900 | 1.0 | 903400 | 10.0 |

| 31/2 lF | 480333600 | 5.0 | 71086001 | 1.0 | 52125001 | 1.0 | 903400 | 10.0 |

| 4R | 480334200 | 7.0 | 71086101 | 1.1 | 16014000 | 1.5 | 904200 | 12.0 |

| 4F | 480334400 | 8.0 | 71086201 | 1.4 | 16014100 | 1.6 | 904400 | 13.0 |

| 5R | 480335200 | 9.0 | 71086301 | 1.6 | 16014200 | 1.6 | 905200 | 15.0 |

| 5F-6R | 480335462 | 12.0 | 71086401 | 1.8 | 16014300 | 2.0 | 905462 | 19.0 |

ORDERING INFORMATION

BAFFLE PLATES

BAFFLE PLATES

Baffle plates can be placed on top of the drill-pipe float valve or the drill bit too help prevent damage from recorders or other wire-line tools that are dropped down the string.

BAFFLE PLATES

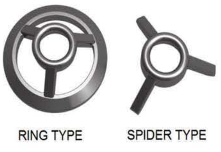

RING-AND-SPIDER TYPE

| Part Number | Connection Type/Size | DPFV Size | Type | Weight (Ibs) | Baffle Plate OD | Usage On/In |

|---|---|---|---|---|---|---|

| 91701 | 27/8" API Reg. | 1F2R | Spider | 0.5 | 1.94" | Bit |

| 91702 | 3 1/2" API Reg. | 2F3R | Ring | 004 | 2.28" | Bit |

| 91703 | 4 1/2" API Reg. | 4R | Ring | 0.8 | 3.22" | Bit |

| 91704 | 5 9/16" API Reg. | 5R | Ring | 1.3 | 3.87" | Bit |

| 91705 | 6 5/8" API Reg. | 5F6R | Ring | 1.5 | 4.63" | Bit |

| 91706 | 7 5/8" API Reg. | 5F6R | Ring | 1.7 | 5.33" | Bit |

| 91707 | 8 5/8" API Reg.8 5/8" API Reg. | 6F | Ring | 2.2 | 6.18" | Bit |

| 91711 | Replaced by 91721 | 3F | Spider | 0.6 | 2.75" | Joint |

| 91712 | 41/2" API FH | 4F | Ring | 0.9 | 3.36" | Joint |

| 91713 | 5 9/16" API FH | 5F6R | Ring | 1.5 | 4.63" | Joint |

| 91714 | 65/8" API FH | 6F | Ring | 2.2 | 5045" | Bit |

| 91721 | 3 1/2" API FH | 3F | Spider | 0.6 | 2.63" | Float |

91722 |

41/2" API FH | 4F | Spider |

0.7 | 3044" | Float |

| 4 1/2" API Reg. | 4R | |||||

| 5 9/16" API Reg. | 5R | |||||

| 91723 | 59/16" FH | 5F6R | Spider | 1.0 | 4.68" | Float |

| 6 5/8" API Reg. | 5F6R | |||||

| 91724 | 65/8" API FH | 6F | Spider | 1.0 | 6.56" | Float |

| 91725 | 3 1/2" API IF | 3.5IF | Spider | 0.6 | 3.06" | Float |

| 91726 | Replaced by 91722 | 5R | Spider | 0.8 | 3.76" | Float |

| 91740 | Replaced by 91743 | 2F3R | Ring | 0.7 | 2.34" | Bit |

| 91741 | 3 1/2" API IF | 3.5IF | Ring | 0.7 | 3.06" | Joint |

| 91742 | 41/2" API IF | 5R | Ring | 1.6 | 4.22" | Joint |

| 91743 | 27/8" API IF | 2F3R | Spider | 0.7 | 2040" | Joint |

| 91744 | 4" API IF/4 1/2" XH | 4F | Ring | 1.0 | 3.88" | Joint |

For over 60 years OTECO, Inc. has been providing high quality oilfield equipment to the worldwide oil and gas markets. Operating from our modern 120,000 square foot manufacturing facility in Houston, Texas, OTECO continues to provide products to the high quality standards for which we are known

OIL FIELD EQUIPMENT PRODUCTS

For over 60 years OTECO, Inc. has been providing high quality oilfield equipment to the worldwide oil and gas markets. Operating from our modern 120,000 square foot manufacturing facility in Houston, Texas, OTECO continues to provide products to the high quality standards for which we are known.

OTECO Model 72 Gate Valve

Details

models

Model72

Model 66

Designed for the oilfield, the Model 72 gate valve is the proven, reliable choice for applications requiring up to 5,000 psi working pressure and 250 deg. F (121 deg. C) temperatures. The Model 72 gate valve is designed for maximum flexibility and reliability and is ideal for corrosive water flood applications, sour gas and crude oil service, as well as certain wellhead applications. Whether used in your mud system, floor and standpipe manifold, or flow line application, the Model 72 is field proven for easy operation, tight shut-offs, long life, and simple, fast, low-cost field renewal. Manufactured at our Houston facility, each Model 72 is rigorously tested prior to shipment from the factory.

Model 72 Features & Benefits

- • Utilization of Body Subs allow change out of valve connections without changing valve body or entire valve.

- • Full rising, one piece forged gate and stem displays current valve orientation: open, partially open, or closed.

- • Extra large ball bearings and heavy duty stem threads minimize torque required for valve operation.

- • Proven interlocking gate packing and wear plate design protects the valve body and cap during repeated valve opening and closing.

- • Standard gate packings are designed for a wide range of fluid environments.

- • Model 72 parts are interchangeable with Cameron type ‘S’ Flex-Seal valve parts.

Model 66

Although no longer in production, Model 66 support and replacement parts are still available. Model 66 parts are interchangeable with Cameron type ‘R’ Flex-Seal valve parts.

OTECO Pressure Relief Valves

Pressure Relief Valve (PRV) Overview

The OTECO type PRV (shear type) Relief Valve helps ensure protection for slush pumps, manifolds, and other expensive components used in drilling operations. The PRV relief valve utilizes shear pins to relieve overpressure during drilling and other operations. Hardened stainless steel stems and stainless steel liner subs provide improved corrosion resistance resulting in higher reliability and longer valve life. With the OTECO PRV pressure relief valve, replacing shear pins is fast and easy because of the easy to remove safety cover. The OTECO PRV is available in 2 inch low, standard, and high pressure, as well as 3 inch high pressure models.

PRV Features & Benefits

- • A metal chart is installed on every valve detailing shear pin selection specifications.

- • Hardened stainless steel stems and liner subs provide corrosion resistance.

- • PRV relief valve parts are interchangeable with Cameron style shear relief valve parts.

Manual Reset Relief Valve

Type RR Overview

The type RR manual reset relief valve protects slush pumps and mud manifolds while guaranteeing greater safety in operation. The RR relief valve automatically snaps to a full open position when the predetermined pressure is exceeded or can be manually opened by simply pressing the manual release button. The position of the release button indicates at a glance whether the valve is open or closed. The RR is designed with a pressure setting indicator (available in metric units) which can be adjusted to any setting within the operating range by simply turning a nut on the top of the valve.

RR Features & Benefits

- • Release pressure setting is not affected by vibration during operation.

- • Utilizes stainless steel piston and Cadmium-plated sub for improved corrosion resistance.

- • Does not require shear pins.

- • Fully enclosed bonnet assembly retains grease coating on moving parts extending service life.

- • Bonnet assembly is interchangeable with Cameron Type ‘A’ and Type ‘B’ reset relief valves.

Valve Rebuilding Service

OTECO can rebuild or exchange your worn or damaged OTECO, Cameron Type ‘A’ or Type ‘B’ reset relief valve bonnet assemblies. Contact your OTECO distributor or sales representative for more information.

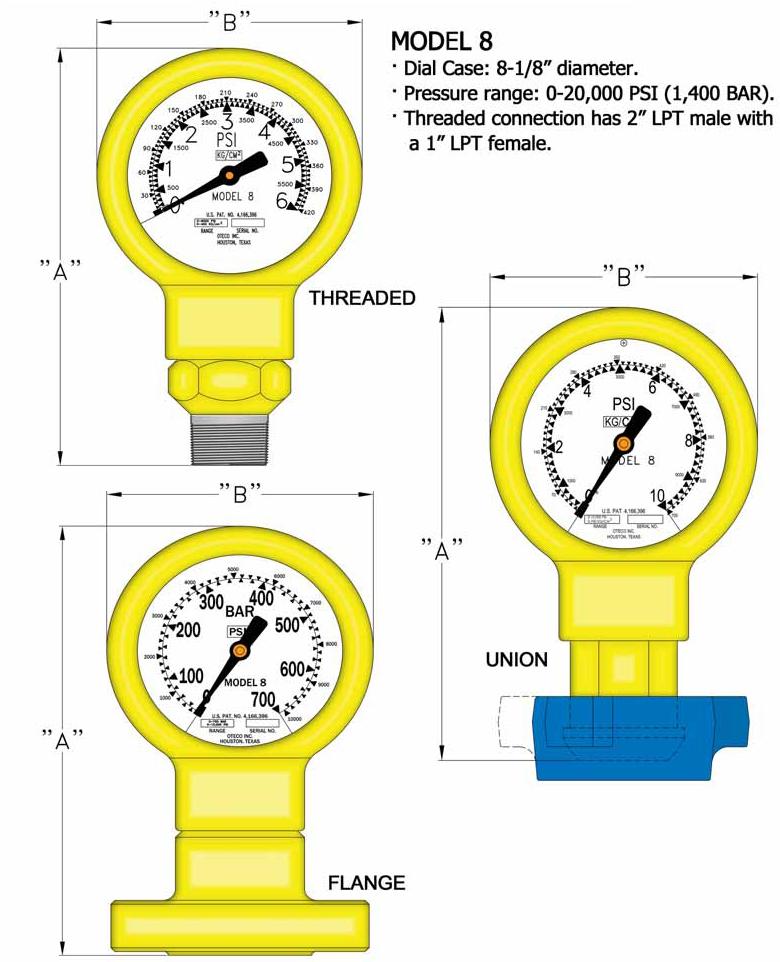

OTECO Pressure Gauges

OTECO pressure gauges have a built in dampening mechanism to minimize wear and mechanical shock. In addition, the heavy duty seals restrict line fluid from entering the gauge mechanism. The gauge mechanism itself is surrounded by a special oil providing resistance to extreme temperatures, as well as vibration and shock. For additional safety, a low pressure plug is installed to prevent gauge case and lens damage. All gauges are available for standard, salt water, sour gas, and oil service.

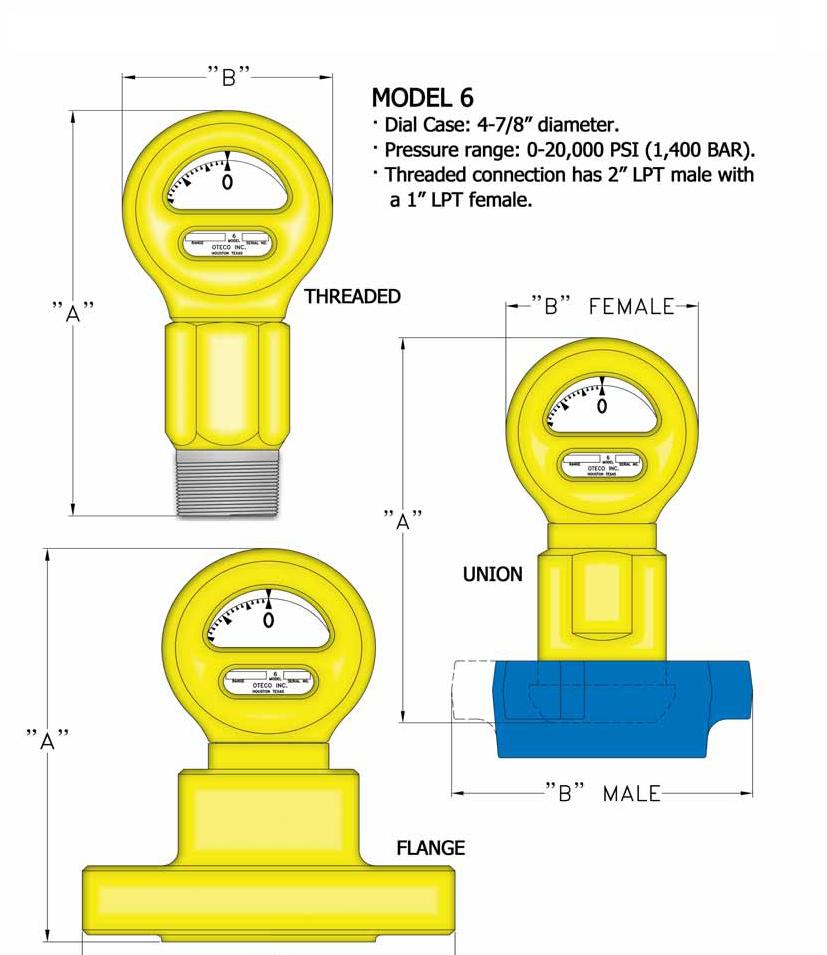

Model 6

- • Standard end connection : combination 2 inch line pipe threaded male with a 1 inch line pipe threaded female connection.

- • Pressure range : 0 - 20,000 psi.

- • Dimensions : 4-7/8 inch diameter dial case and 9-7/8 inch in height.

- • Interchangeable with : Cameron type ‘F’, Totco type ‘6’, Geosource type ‘F’, Wadeco model ‘10’, and Gauges International model ‘6’.

Model 7

- • Standard end connection : 2 inch line pipe threaded female connection.

- • Pressure range : 0 - 6,000 psi.

- • Dimensions : 7-5/8 inch diameter dial case and 14-3/4 inch in height.

- • Interchangeable with : Cameron type ‘D’, Totco type ‘4’, Geosource type ‘D’, Wadeco model ‘12’, and Gauges International model ‘7’.

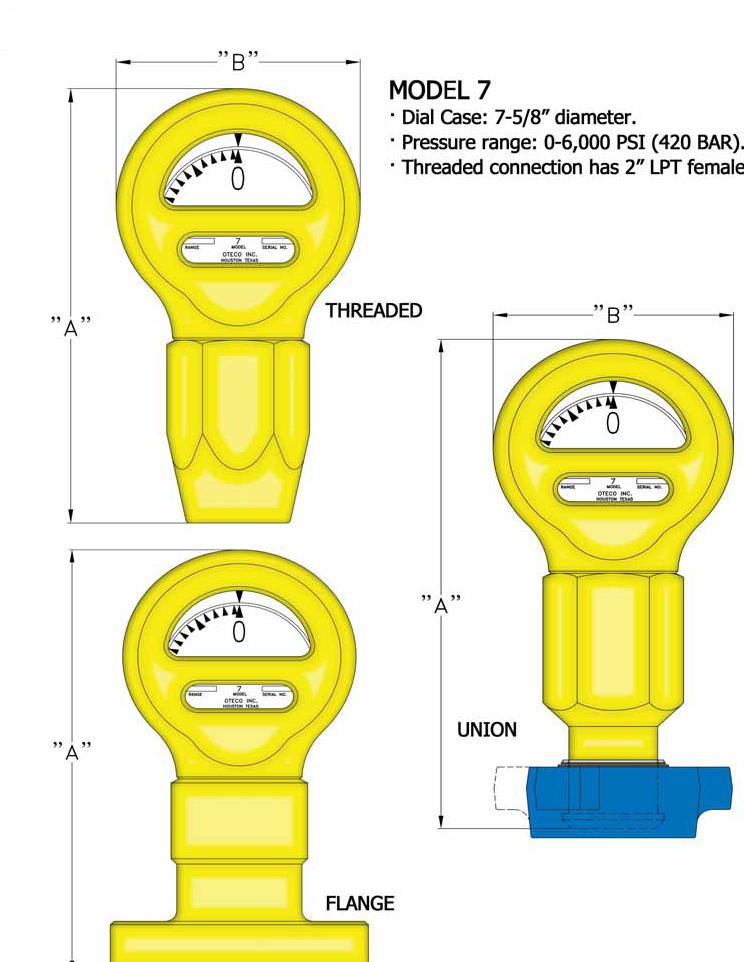

Model 8

- • Standard end connection : combination 2 inch line pipe threaded male with a 1 inch line pipe threaded female connection.

- • Pressure range : 0 - 20,000 psi.

- • Dimensions : 8-1/8 inch diameter dial case and 13-1/4 inches in height.

- • Large 6 inch dial face incorporates a tough, impact resistant acrylic lens.

- • Dual unit-of-measure dial face available.

Gauge Rebuilding Service

We offer gauge rebuilding and refurbishment services. We can repair worn or damaged gauges to “like new” condition. The new or rebuilt pressure gauge is packed in an individual cardboard box with a thick layer of foam protecting the gauge itself.

Manifold Fittings

OTECO manufactures ten different styles of manifold fittings in 2 inch, 3 inch, 4 inch, and 5 inch with working pressures ranging from 3,000 psi to 5,000 psi with test pressures up to 10,000 psi. Each fitting can be supplied with either line pipe threads, or Schedule XX or 160 buttweld end connections. Special connections are available upon request. All fittings are hydrostatically tested prior to shipment and full certification can be supplied upon request.

Available OTECO Manifold Fittings include:

- • 45º Long Sweep Ells

- • 90º Long Sweep Ells

- • 90º Long Sweep Ells with 2 in. outlet

- • 160º Standpipe Gooseneck

- • 160º Standpipe Gooseneck with top outlet

- • 180º Standpipe Gooseneck

- • Long Sweep Full Flow Cross

- • Long Sweep Full Flow Tee

- • Long Sweep Tee

- • Long Sweep Y

Standpipe and Manifold Assembly Fabrication Services OTECO manufactures to customer specifications complete 5,000 psi standpipe manifold assemblies. Every standpipe manifold is sandblasted, epoxy-coated and thoroughly tested prior to shipment.

Wireline Equipment

OTECO manufactures wireline turnback assemblies and components. In addition, we have replacement rollers for BJ model code Roliguide. OTECO also offers complete wireline guide units and wireline guide hanging assemblies for most beam or angle type derricks.

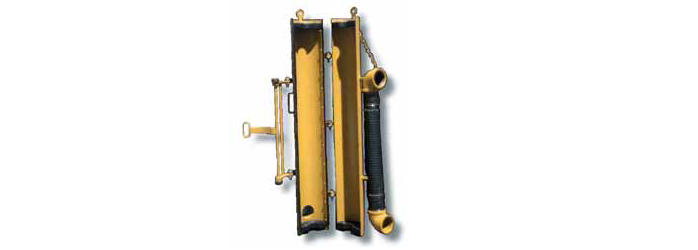

Mud Guards

OTECO mud guards come in two models: the MG-600 and MG-800. Our mud guards have proven cost effective in saving the expense of lost drilling fluids, reduced labor for rig wash down, as well as reducing the potential for accidents due to slippery rig floors. The MG-600 is 6 ft. x 10-3/4 in. and can handle drill pipe sizes from 2-3/8 in. to 5-1/2 in. The MG-800 is 6 ft. x 16 in., it’s larger cavity is designed for drill pipe sizes from 2-3/8 in. to 6-5/8 in. and can handle larger volumes of line fluids. Both models can be supplied with neoprene or nitrile end and side seals.

Oil Guards

Similar in design to our mud guards, the OTECO Oil Guard MG-500 is 4 ft. x 6 in. and is designed to accommodate tubing sizes ranging from 2-3/8 in. to 3-1/2 in.

BOP and Control Head Products

OTECO provides replacement packing units and seals for the Hydril ‘GK’ & ‘MSP’ and Regan type ‘K’ annular blow out preventors. These items are available in natural, neoprene, and nitrile rubber compounds with each unit tested to its full working pressure prior to shipment. In addition, OTECO offers replacement rubbers for Shaffer type ‘39’, Guiberson types ‘A’ & ‘B’, and Cameron types ‘QRC’, ‘SS’, and ‘U’ ram type blow out preventors.

Diaphragms & Bladders

OTECO supplies replacement diaphragms and parts for the Hydril and Mattco 10 and 20 gallon pulsation dampeners. These diaphragms are molded in one piece and are available in 1500 psi, 3000 psi, and 5000 psi ratings. They also have a metal insert molded into the bottom to prevent extrusion into the bottom flange connection. Stabilizers, plates, screws, lock washers, bottom plate gaskets, charging valves, and pressure gauges (0-6000 psi) are also available. OTECO also supplies replacement bladders for the Pioneer Solidsmaster (3 in.), Sandmaster (6 in.) and Siltmaster (4 in.) made from durable nitrile compounds.

Pipe and Kelly Wipers

OTECO offers a wide range of pipe and kelly wipers. These pipe wipers are offered in single, double, oval, and handle bar types and are available in either natural (black), and oil resistant (red) nitrile rubber compounds. In addition, the double wipers are available in solid, split, and split rap-a-round configurations. OTECO pipe wipers offer greater tearing resistance due to a reinforced insert molded to the resilient live rubber. OTECO kelly wipers are molded from the same high quality rubber as the pipe wipers and are offered for both square and hexagonal kellys. The kelly wipers are reinforced with a bonded metal ring to provide longer service life for the wiper as well as the kelly drive bushing.

Rotating BOP & Tubing Stripper Rubbers

OTECO manufactures a wide range of models and sizes of rotating BOP and tubing stripper rubbers. The current rotating BOP models offered include the interchangeable parts for the Shaffer Type 50, 74, 79, Lynn International, Shaffer 51, and the Grant 7068. Tubing stripper rubbers are offered for the following stripper heads :

- • Beaumont Iron Works PX-70 and PX-107

- • Cameron Petromec PC & QD

- • Guiberson Type J2 & JU

- • Gulfco Type TT & S6

- • Hillerman Kelley Type HK

- • Hinderliter Type SS, 4-S, & 4-1

- • Hydril Type RS

- • Larkin Type K & SR

- • Norris Hinderliter 4-1

- • Oil Center Tool Type J-1, JF-1, Type T-16

- • Rector Type R and Type SS

Bonded Urethane and Premium Pistons

OTECO’s innovative bonded polyurethane piston dramatically extends service life in triplex mud pumps with ample water cooling. Harder, more dense polyurethane construction provides superior resistance to abrasive fluids providing optimum service life in harsh drilling conditions. In addition, the urethane construction is especially resistant to chemicals and oil based drilling muds with varying aniline points. The multi-ply, fabric reinforced backing used in the production of the piston rubbers provide positive, wear resistant seals. High tensile strength, resistance to chemicals, hydrocarbons, and abrasion, long lasting service, and full interchangeability with other API designed pistons makes the OTECO Premium piston a sound value.

Premium Stem Guided Valves & Seats

The OTECO premium stem guided valve and seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert. The premium stem guided valve and seat provide good value, are economically priced, and weigh less than many competitors valve and seat.

Washpipe & Packing

OTECO washpipe is precision ground for exact alignment of all flanges, threads, and packing. Each piece is manufactured from high quality alloy steel which is hard surfaced in all critical wear areas for corrosion and wear resistance. Our washpipe packing is molded from a fabric and synthetic composition what has been impregnated with a rubber compound highly resistant to water, oil, and abrasion.

Piston Rods and other Accessories

In addition to the above products, OTECO also offers a full complement of premium and induction hardened piston rods, crosshead extension rods, valve and cylinder head gaskets, and rod clamps.

OTECO Connector

The OTECO Connector serves the same function as a high pressure flanged assembly. The hub element is the equivalent of a flange, the clamps serve the same purpose as flange bolts, and the seal ring acts as the pressure gasket. The OTECO connector is used in extreme conditions where corrosive or dangerous fluids are present and/ or elevated or cryogenic temperatures are encountered.

- • Available in Standard sizes 1 inch to 12 inches and Heavy Duty sizes B to F

- • The OTECO Connector is much smaller and lighter than a standard flanged connection

- • Requires minimum assembly and disassembly time

- • The OTECO Connector is competitively priced

- • Features precisely manufactured components made from certifiable materials

OTECO Shock Pads

OTECO manufactures shock pads for offshore rig jacking systems. Each pad is made with specially formulated rubber, molded between layers of corrosion resistant steel plates and is tested under load prior to shipment. This product is available upon request only and is custom manufactured to meet your specific requirements. For more information please contact our Houston office or your nearest OTECO distributor or sales representative.

Manifold Fittings

For over 60 years OTECO, Inc. has been providing high quality oilfield equipment to the worldwide oil and gas markets.

Operating from our modern 120,000 square foot manufacturing facility in Houston, Texas, OTECO continues to provide products to the high quality standards for which we are known.

2" 5k Manifolt Fittings

DIMENSIONAL

CHART

FFC, LSFFT, LST, LSE45, LSE90, LS4

"A" |

"B" |

"D" |

"E |

"G" |

"K" |

"L" |

"P" |

"Q" |

"R" |

"S" |

"T" | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches MM |

3.50 88.9 |

16.00 406.4 |

8.00 203.2 |

4.25 108.0 |

3.75 95.3 |

2.50 63.5 |

4.25 108.0 |

4.13 104.9 |

12.00 304.8 |

10.00 79.5 |

11.38 289.1 |

3.13 254.0 |

Note: On butt weld fittings, the weld bevel is 37.5°. The O.D. and the I.D. of the weld end fittings match ANSI B36.10. Dimensions are applicable to both weld end and screwed end fittings.

2" 5k Manifold Fittings

| Item # | 2" Manifold Description |

Max.PSI |

Press(BAR) |

Weight(LBS) |

|---|---|---|---|---|

412101 412103 412104 |

FULL FLOW CROSS,2222X,2" LPT FULL FLOW CROSS,2222X,2" BW SCH.160 FULL FLOW CROSS,2222X,2" BW SCH.XXS |

5,000 5,000 5,000 |

(345) (345) (345) |

110 110 110 |

|

412071 412073 412074 |

LONG SWEEP ELL,22L45,2" LPT LONG SWEEP ELL,22L45,2" BW SCH.160 LONG SWEEP ELL,22L45,2" BW SCH.XXS |

51000 5,000 5,000 |

(345) (345) (345) |

12 12 12 |

|

412061 412015 412063 412064 |

LONG SWEEP ELL,22L90,2" LPT LONG SWEEP ELL,22L90,2" BW SCH.80 LONG SWEEP ELL,22L90,2" BW SCH.160 LONG SWEEP ELL,22L90,2" BW SCH.XXS |

5,000 3,000 5,000 5,000 |

(345) (207) (345) (345) |

30 30 30 30 |

|

412011 412016 412013 412014 |

LONG SWEEP FULL FLOW TEE,222T,2" LPT LONG SWEEP FULL FLOW TEE,2221,2" BW SCH.80 LONG SWEEP FULL FLOW TEE,222T,2" BW SCH.160 LONG SWEEP FULL FLOW TEE,2221,2" BW SCH.XXS |

5,000 3,000 5,000 5,000 |

(345) (207) (345) (345) |

51 51 51 51 |

|

412021 412023 412024 |

LONG SWEEP TEE,222LST,2" LPT LONG SWEEP TEE,222L5T,2" BW SCH.160 LONG SWEEP TEE,222LST,2" BW SCH.XXS |

5,000 5,000 5,000 |

(345) (345) (345) |

60 60 60 |

|

412091 412093 412094 |

LONG SWEEP Y,222Y,2" LPT LONG SWEEP Y,222Y,2" BW SCH.160 LONG SWEEP Y,222Y,2" BW SCH.XXS |

5,000 5,000 5,000 |

(345) (345) (345) |

51 51 51 |

Note: Sour gas service available.

Castings are made from ASTM A216 Grade WCC.

Special end connections available upon request.

Sch.80 end connections rated at 3K PSI working pressure.

Material tensile and chemical properties available upon request

3" 5k Manifolt Fittings

DIMENSIONAL

CHART

LSFFT, GSNKTO, LST, LSE90, GSNK160, LSE45

"A" |

"B" |

"C" |

"D |

"E" |

"F" |

"G" |

"H" |

"J" |

"K" |

"L" |

"M" |

"N" |

"P" |

"Q" |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches MM |

4.88 124.00 |

20.00 508.0 |

12.00 304.8 |

10.00 254.0 |

5.13 130.3 |

4.75 120.7 |

5.13 130.3 |

3.01 76.5 |

12.00 308.4 |

3.11 79.0 |

5.31 134.9 |

5.06 128.5 |

2.89 73.4 |

5.00 127.0 |

14.75 374.7 |

Note: On butt weld fittings, the weld bevel is 37.5°. The O.D. and the I.D. of the weld end fittings match ANSI B36.10. Dimensions are applicable to both weld end and screwed end fittings.

3" 5k Manifold Fittings

| Item # | 3" Manifold Description |

Max.PSI |

Press(BAR) |

Weight(LBS) |

|---|---|---|---|---|

413051 413053 413054 |

GOOSENECK 160° W/TOP OUTLET,333GT0,3" LPT GOOSENECK 1600 W/TOP OUTLET,333GT0,3" SW SCH.160 GOOSENECK 1600 W/TOP OUTLET,333GT0,3" BW SCH.XXS |

3,000 5,000 5,000 |

((207) (345) (345) |

105 105 105 |

|

413031 413033 413034 |

GOOSENECK 160°,33G6,3" LPT GOOSENECK 160°,33G6,3" BW SCH.160 GOOSENECK 160°,33G6,3" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

82 82 82 |

|

413071 413073 413074 |

LONG SWEEP ELL,33L45,3" LPT LONG SWEEP ELL,33L45,3" BW SCH.160 LONG SWEEP ELL,33L45,3" SW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

20 20 20 |

|

413061 413063 413064 |

LONG SWEEP ELL,33L90,3" LPT LONG SWEEP ELL,33L90,3" BW SCH.160 LONG SWEEP ELL,33L90,3" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

67 67 67 |

|

413011 413013 413014 |

LONG SWEEP FULL FLOW TEE,333T,3" LPT LONG SWEEP FULL FLOW TEE,333T,3" BW SCH.160 LONG SWEEP FULL FLOW TEE,333T,3" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

97 97 97 |

|

413021 413023 413024 |

LONG SWEEP TEE,333LS1,3" LPT LONG SWEEP TEE,333LS1,3" SW SCH.160 LONG SWEEP TEE,333LST13" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

80 80 80 |

Note:Sour gas service available.

Castings are made from ASTM A216 Grade WCC.

Special end connections available upon request.

Sch.80 B.W. & 3" L.P.T. end connections rated at 3K PSI working pressure. Material tensile and chemical properties available upon request.

4" 5k Manifolt Fittings

DIMENSIONAL

CHART

FFC, LSY, GSNKTO, LST, LSE90, 424LSE90, LSE45, GSNK160, GSNK180, LSFFT

"A" |

"B" |

"C" |

"D |

"E" |

"F" |

"G" |

"H" |

"J" |

"K" |

"L" |

"M" |

"N" |

"P" |

"S" |

"T" |

"U" |

"V" |

"W" |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches MM |

5.69 144.5 |

22.00 558.8 |

16.00 406.4 |

11.00 279.4 |

5.50 139.7 |

5.00 127.0 |

6.25 158.8 |

3.59 91.2 |

14.00 355.6 |

6.38 162.1 |

10.88 276.4 |

5.66 143.8 |

3.63 92.2 |

5.75 146.1 |

19.63 498.6 |

4.16 105.7 |

3.50 88.9 |

5.38 136.7 |

4.03 102.4 |

Note: On butt weld fittings, the weld bevel is 37.5°. The O.D. and the I.D. of the weld end fittings match ANSI B36.10. Dimensions are applicable to both weld end and screwed end fittings.

4" 5k Manifold Fittings

| Item # | 4" Manifold Description |

Max.PSI |

Press(BAR) |

Weight(LBS) |

|---|---|---|---|---|

414101 414103 414104 |

FULL FLOW CROSS 4444X,4" LPT FULL FLOW CROSS 4444X,4" BW SCH.160 FULL FLOW CROSS 4444X,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

206 206 206 |

|

414051 414053 414054 |

GOOSENECK 160° W/TOP OUTLET,444GT0,4" LPT GOOSENECK 160° W/TOP OUTLET,444GT0,4" BW SCH.160 GOOSENECK 160° W/TOP OUTLET,444GT0,4" BWSCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

142 142 142 |

|

414031 414033 414034 |

GOOSENECK 160°,44G6,4" LPT GOOSENECK 160°,44G6,4" OW SCH.160 GOOSENECK 160°,44G6,4" SW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

109 109 109 |

|

414041 414043 414044 |

GOOSENECK 180°,44G8,4" LPT GOOSENECK 180°,44G8,4" OW SCH.160 GOOSENECK 180°,44G8,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

129 129 129 |

|

414081 414083 414084 |

LONG SWEEP ELL W12" TOP OUTLET,424L90,4X2X4 LPT LONG SWEEP ELL W12" TOP OUTLET,424L90,4" BW SCH.160 LONG SWEEP ELL W12" TOP OUTLET,424L90,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

95 95 95 |

|

414071 414073 414074 |

LONG SWEEP ELL,44L45,4" LPT LONG SWEEP ELL,44L45,4" BW SCH.160 LONG SWEEP ELL,44L45,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

55 55 55 |

|

414061 414062 414063 414064 |

LONG SWEEP ELL,44L90,4" LPT LONG SWEEP ELL,44L90,4" BW SCH.80 LONG SWEEP ELL,44L90,4" BW SCH.160 LONG SWEEP ELL,44L90,4" BW SCH.XXS |

3,000 3,000 5,000 5,000 |

(207) (207) (345) (345) |

87 87 87 87 |

|

414011 414013 414014 |

LONG SWEEP FULL FLOW TEE,444T,4" LPT LONG SWEEP FULL FLOW TEE,444T,4" BW SCH.160 LONG SWEEP FULL FLOW TEE,444T,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

140 140 140 |

|

414021 414023 414024 |

LONG SWEEP TEE,444L5T,4" LPT LONG SWEEP TEE,444L5T,4" BW SCH.160 LONG SWEEP TEE,444L5T,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

115 115 115 |

|

414091 414093 414094 |

LONG SWEEP 7,4447,4" LPT LONG SWEEP 7,4447,4" BW SCH.160 LONG SWEEP 7,4447,4" BW SCH.XXS |

3,000 5,000 5,000 |

(207) (345) (345) |

162 162 162 |

| Note:Sour Sour gas service available. Castings are made from ASTM 4216 Grade WCC. Spedal end connections available upon request. 546.80 B.W. &4" L.P.T. end connections rated at 3K PSI working pressure. Material tensile and chemical properties available upon request |

5" 5k & 7.5 Manifolt Fittings

DIMENSIONAL

CHART

FFC, LSFFT, GSNKTO, LST, LSE90, 525LSE90, LSE45, GSNK160, GSNK180

"A" |

"B" |

"C" |

"D |

"E" |

"F" |

"G" |

"H" |

"J" |

"K" |

"L" |

"N" |

"P" |

"U" |

"V" |

"W" |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches MM |

6.81 173.0 |

24.00 609.6 |

19.00 482.6 |

12.00 304.8 |

5.50 139.7 |

7.00 177.8 |

7.25 184.2 |

4.25 108.0 |

16.00 406.4 |

6.74 171.2 |

11.50 292.1 |

3.75 95.3 |

6.00 152.4 |

3.50 88.9 |

5.88 149.4 |

4.47 113.5 |

Note: On butt weld fittings, the weld bevel is 37.5°. The O.D. and the I.D. of the weld end fittings match ANSI B36.10. Dimensions are applicable to both weld end and screwed end fittings.

5" 5k & 7.5K Manifold Fittings

| Item # | 5" Manifold Description |

Max.PSI |

Press(BAR) |

Weight(LBS) |

|---|---|---|---|---|

415103 415104 417035 |

FULL FLOW CROSS,5555X,5" BW SCH.160 FULL FLOW CROSS,5555X,5" BW SCH.XXS FULL FLOW CROSS,5555X,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

515 515 515 |

|

415053 415054 417055 |

GOOSENECK 160 W/TOP OUTLET,555GT0,5" BW SCH.160 GOOSENECK 160' W/TOP OUTLET,555GT0,5" BW SCH.XXS GOOSENECK 160' WiTOP OUTLET,555GT0,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

220 220 220 |

|

415033 415034 |

GOOSENECK 160,55G6,5" BW SCH.160 GOOSENECK 160,55G6,5" BW SCH.XXS > |

35,000 5,000 |

(345) (345) |

200 200 |

|

415043 415044 |

GOOSENECK 180',55G8,5" BW SCH.160 GOOSENECK 180',55G8,5" BW SCH.XXS > |

5,000 5,000 |

(345) (345) |

220 220 |

|

415083 415084 |

LONG SWEEP ELL W/2" TOP OUTLET,525L90,5" BW SCH.160 LONG SWEEP ELL W12" TOP OUTLET,525L90,5" BW SCH.XXS |

5,000 5,000 |

(345) (345) |

140 140 |

|

415073 415074 417045 |

LONG SWEEP ELL,55L45,5" BW SCH.160 LONG SWEEP ELL,55L45,5" BW SCH.XXS LONG SWEEP ELL,55L45,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

74 74 74 |

|

415063 415064 417005 |

LONG SWEEP ELL,55L90,5" BW SCH.160 LONG SWEEP ELL,55L90,5" BW SCH.XXS LONG SWEEP ELL,55L90,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

87 87 87 87 |

|

415013 415014 417025 |

LONG SWEEP FULL FLOW TEE,555T,5" BW SCH.160 LONG SWEEP FULL FLOW TEE,555T,5" BW SCH.XXS LONG SWEEP FULL FLOW TEE,555T,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

200 200 200 |

|

415023 415024 417015 |

LONG SWEEP TEE,555LS1,5" BW SCH.160 LONG SWEEP TEE,555LST,5" BW SCH.XXS LONG SWEEP TEE,555L5T,5" BW SCH.XXS |

5,000 5,000 7,500 |

(345) (345) (517) |

161 161 161 |

Note: Sour gas service available.

5K Castings are made from ASTM A216 Grade WCC.

7.5K Castings are made from ASTM A487 Grade 4D Modified.

Special end connections available upon request.

Material tensile and chemical properties available upon request.

5" 8k Extra Heavy Wall Fittings

DIMENSIONAL

CHART

FFC, LSFFT, GSNKTO, LST, LSE90, LSE45

"A" |

"B" |

"C" |

"D |

"E" |

"F" |

"G" |

"H" |

"J" |

"K" |

"L" |

"M" |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches MM |

8.88 225.6 |

26.00 660.4 |

21.00 533.4 |

13.00 330.2 |

4.81 122.2 |

8.00 203.2 |

13.25 336.6 |

3.19 681.0 |

17.00 431.8 |

7.75 196.9 |

4.94 125.5 |

9.25 235.0 |

Note: On butt weld fittings, the weld bevel is 37.5°. The O.D. and the I.D. of the weld end fittings match ANSI B36.10. Dimensions are applicable to both weld end and screwed end fittings.

5" 8k Extra Heavy Wall Fittings

| Item # | 5" 8K Extra Heavy Wall Manifold Description |

Max.PSI |

Press(BAR) |

Weight(LBS) |

|---|---|---|---|---|

418035 |

FULL FLOW CROSS,5555X,5" BW SCH.XXS |

8,000 |

(552) |

581 |

418055 |

GOOSENECK 160 W/TOP OUTLET,5550T0,5" BW SCH.XXS |

8,000 |

(552) |

435 |

418045 |

LONG SWEEP ELL,55L45,5" BW SCH.XXS |

8,000 |

(552) |

203 |

418005 |

LONG SWEEP ELL,55L90,5" BW SCH.XXS |

8,000 |

(552) |

352 |

418025 |

LONG SWEEP FULL FLOW TEE,555T,5" SW SCH.XXS |

8,000 |

(552) |

436 |

418015 |

LONG SWEEP TEE,555LST,5" BW SCH.XXS |

8,000 |

(552) |

314 |

Note: Sour gas service available.

Castings are made from ASTM A487 Grade 4D Modified.

Special end connections available upon request in Sch.)0(.5 only.

Material tensile and chemical properties available upon request

| Most manifold fittings are machined to exceptional tolerances using single chucking on horizontal machining centers. Buttweld and screwed API line pipe connections are available in 2 inch, 3 inch and 4 inch sizes. Five inch and six inch are available with buttweld connections. Special end connections such as socketweld and metric values available upon request. All fittings are hydrostatically tested to a minimum of 1-1/2 times working pres¬sure. See chart below for values. |

MAXIMUM WORKING & TEST PRESSURES

FOR FITFINGS PSI (BAR)

| NOMINAL PIPE SIZE |

SCH. 40 | SCH. 80 | SCH. 120 | SCH. 160 | SC)!. XXS | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| W.P. | TA'. | W.I'. | T.P. | W.P. | T.P. | W.V. | T.P. | W.P. | T.P. | |

| 2" | 2,0(X) (138) |

4.000 (276) |

3.000 (207) |

MOO (414) |

5.000 (345) |

7.500 (517) |

5,000 (345) |

(URN) (689) |

||

| 3" | 2.0(X) (138) |

4,000 (276) |

3,000 (207) |

6.0(X) (414) |

5.000 (345) |

7.500 (517) |

5,0(X) (345) |

10.000 (689) |

||

| 4" | 2.00() (138) |

3.000 (207) |

3.000 (207) |

4.5(X) (310) |

4,000 (276) |

6.0(X) (414) |

5.0(X) (345) |

7.500 (517) |

5.000 (345) |

10.000 (689) |

| 5" | 2.000 (138) |

3,000 (207) |

3,01X) (207) |

4.500 (310) |

4,000 (276) |

6,000 (414) |

5,0(X) (345) |

7.500 (517) |

5.0(X) (345) |

10.0(X) (689) |

| 5" 7.5K | 7.500 (517) |

11.250 (776) | ||||||||

| 5" 8K ELIV1' |

HIGH PRESSURE MANIFOLD nrri NGS MADE FOR SCH.XXS ONLY | 8'00° (552) |

12,000 (827) | |||||||

| 6" 8k | 8.000 (552) |

12.000 (827) | ||||||||

| A.P.I. L.P.T | 2" | 3" | 4" | 5" |

| W.P. | 5.000 (345) |

3.000 (207) |

3.000 (207) |

N/A |

| T.P. | 10.000 (689) |

6.0(X) (414) |

6.000 (414) |

N/A |

Advanced Manufacturing at our Houston, Texas Facility

MODEL 72 GATE VALVE GENERAL

Model 72 Gate Valve

Designed for the oilfield, the Model 72 gate valve is the proven, reliable choice for applications requiring up to 5,000 psi (345 bar) working pressure and 250°F (121°C) temperature. The Model 72 gate valve is ideal for corrosive water flood applications, sour gas and crude oil service, as well as certain wellhead applications. Whether used in your mud system, floor and standpipe manifold, or flow line application, the Model 72 is field proven for easy operation, tight shut-offs, long life, and simple, fast, low-cost field renewal. Manufactured in our Houston, Texas facility to high standards and rigorously tested prior to shipment ensures a quality valve for years of reliable field service.

Model 72 Features & Benefits

- Utilization of body subs allow change out of valve connections without replacing entire valve.

- Body subs for most valve connections including LPT, CSG, LCSG, EUE, NUE, Buttweld Sch.40 though XXS & metric, FMC Weco Hammer Union, and API & ANSI Flanged with custom end connections available upon request.

- Full rising one piece forged gate and stem display the current valve orientation as either open, partially open, or closed.

- Standard gate packings and components for a wide range of fluid environments.

- Five Inch end connections are based on the four inch valve's four inch port.

Recommended Maximum Working Pressure (WP) and Shell Test Pressure (TP)

by End Connection PSI BAR

| 2-Inch Working Pressure | 3-Inch Working Pressure | 4-Inch Working Pressure | 5-Inch (4-Inch Full Port) Working Pressure | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| END CONNECTION (WP) | GV224 2,000 (138) |

GV236 3,000 (207) |

GV250 5,000 (345) |

GV224 2,000 (138) |

GV336 3,000 (207) |

GV350 5,000 (345) |

GV424 2,000 (138) |

GV436 3,000 (207) |

GV450 5,000 (345) |

0V524 2,000 (138) |

GV536 3,000 (207) |

GV550 5,000 (345) |

| Line Pipe Thread (TP) | 4.000 (276) |

6,000 (414) |

10.000 (689) |

4.000 (276) |

6.000 (414) |

7.500 (517) |

4.000 (276) |

6.000 (414) |

7,500 (517) |

4.000 (276) |

6.000 (414) |

NA |

| Butt Weld SCH.40 (TP) | 4.000 (276) |

NR | NR | 4,000 (276) |

NR | NR | 3.000 (207) |

NR | NR | NA | NR | NR |

| Butt Weld SCH.80 (TP) | 4.000 (276) |

6,000 (414) |

NR | 4.000 (276) |

6.000 (414) |

NR | 4.000 (276) |

4.500 (310) |

NR | 4.000 (276) |

NA | NR |

| Butt Weld SCH.160 (TP) | 4.000 (276) |

6.000 (414) |

7,500 (517) |

4,000 (276) |

6,000 (414) |

7,500 (517) |

4.000 (276) |

6.000 (414) |

7,500 (517) |

4.000 (276) |

6.000 (414) |

7.500 (517) |

| Butt Weld SCH.XXS (TP) | 4.000 (276) |

6.000 (414) |

10.000 (689) |

4,000 (276) |

6.000 (414) |

10,000 (689) |

4.000 (276) |

6.000 (414) |

10.000 (689) |

4.000 (276) |

6.000 (414) |

10.000 (689) |

| Raised Face (TP) Flange (ANSI) | 4.000 (276) |

6.000 (414) |

10.000 (689) |

4,000 (276) |

6.000 (414) |

10.000 (689) |

4.000 (276) |

6.000 (414) |

10.000 (689) |

4,000 (276) |

6.000 (414) |

10.000 (689) |

| RTJ Flange (TP) (API) | 4.000 (276) |

6,000 (414) |

10,000 (689) |

4,000 (276) |

6,000 (414) |

10,000 (689) |

4.000 (276) |

6.000 (414) |

10,000 (689) |

4.000 (276) |

6,000 (414) |

10,000 (689) |

| Weer Figure 1002' (TP) | 4.000 (276) |

6,000 (414) |

10,000 (689) |

4,000 (276) |

6,000 (414) |

10,000 (689) |

4.000 (276) |

6.000 (414) |

10,000 (689) |

4.000 (276) |

6,000 (414) |

10,000 (689) |

| Weco Figure 1502 (TP) | 4.000 (276) |

6,000 (414) |

10,000 (689) |

4,000 (276) |

6,000 (414) |

10,000 (689) |

4.000 (276) |

6.000 (414) |

10,000 (689) |

4.000 (276) |

6,000 (414) |

10,000 (689) |

Color coded models match their wpm entational dimensional charts.

Directional leak test is perfo med at the Working Pressure (WP).

• Sour Gas applications reduces working and test pressure.

NA • Not Applicable

NR • Not Recommended

Weco° is a federally registered mark owned by FMC Technologies.

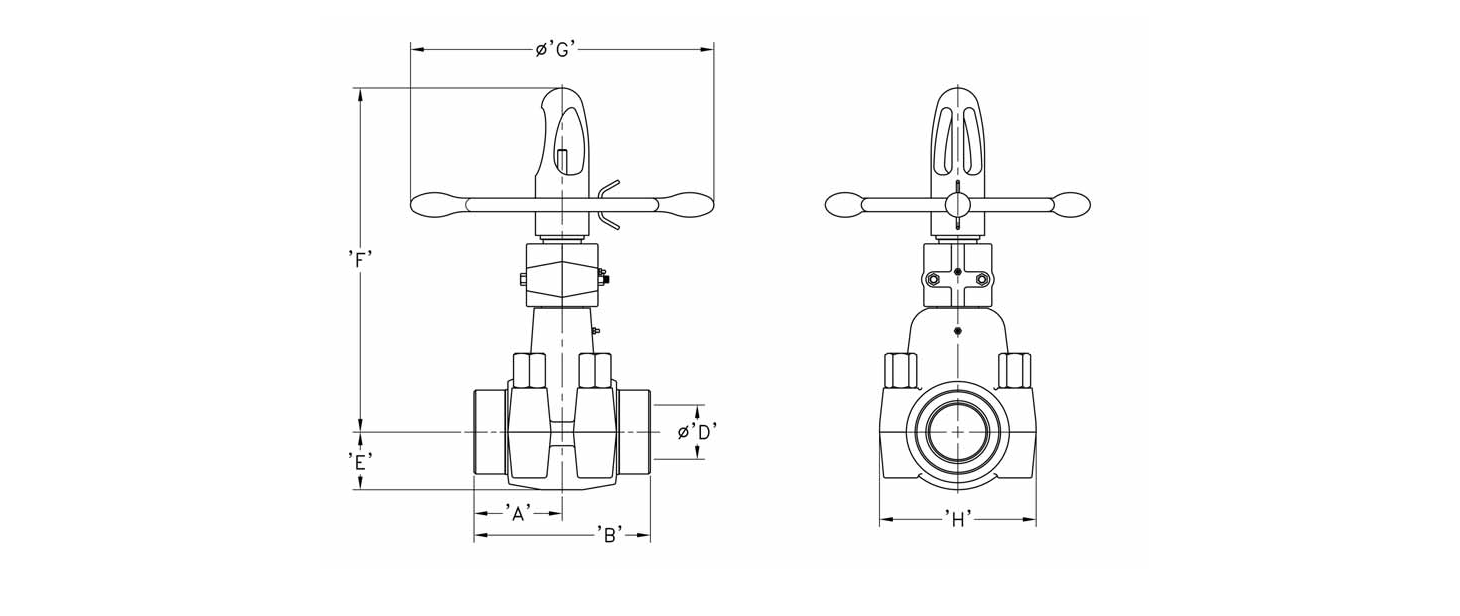

MODEL 72 GATE VALVE DIMENSIONS

Line Pipe Threaded Gate Valve Assemblies - Inch (Metric mm)

| DESCRIPTION | 'A' | 'B' | 'D' | 'E' | 'F' | 'G' | 'H' |

|---|---|---|---|---|---|---|---|

| GV224.THREADED GATE VALVE.2"LP | 3.69 | 7.38 | 2.06 | 2.38 | 13.19 | 14.00 | 7.88 |

| (93.7) | (187.5) | (52.3) | (60.5) | (335.0) | (355.6) | (200.2) | |

| GV236/250.THREADED GATE VALVE,2"LP | 4.50 | 9.00 | 2.06 | 2.81 | 16.00 | 17.00 | 7.56 |

| (114.3) | (228.6) | (52.3) | (71.4) | (406.4) | (431.8) | (192.0) | |

| GV324.THREADED GATE VALVE.3"LP | 4.25 | 8.50 | 3.06 | 3.31 | 19.00 | 17.00 | 9.38 |

| (108) | (215.9) | (77.7) | (84.1) | (482.6) | (431.8) | (238.3) | |

| GV336/350,THREADED GATE VLAVE,3"LP | 5.50 | 11.00 | 3.06 | 3.69 | 21.00 | 20.00 | 10.00 |

| (139.7) | (279.4) | (77.7) | (93.7) | (533.4) | (508) | (254) | |

| GV424.THREADED GATE VALVE.4"LP | 5.50 | 11.00 | 4.06 | 3.88 | 23.88 | 20.00 | 10.63 |

| (139.7) | (279.4) | (103.1) | (98.55) | (606.6) | (508) | (270.0) | |

| GV436/450.THREADED GATE VALVE,4"LP | 6.50 | 13.00 | 4.06 | 4.25 | 25.25 | 22.00 | 11.38 |

| (165.1) | (330.2) | (103.1) | (108) | (641.4) | (558.8) | (289.1) | |

| GV524,THREADED GATE VALVE,5"LP | 6.50 | 12.00 | 4.06 | 3.88 | 23.88 | 20.00 | 10.63 |

| (165.1) | (304.8) | (103.1) | (98.55) | (606.6) | (508) | (270.0) | |

| GV536/550.THREADED GATE VALVE,5"LP | 7.28 | 14.56 | 4.06 | 4.25 | 25.25 | 22.00 | 11.38 |

| (184.9) | (369.8) | (103.1) | (108) | (641.4) | (558.8) | (289.1) |

" Dimensional values are reference. Custom and non-standard end connections will differ.

Butt Weld Gate Valve Assemblies (all schedules) - Inch (Metric mm)